Introduction: Sodium Cyanide

Sodium cyanide, as an important raw material in the industrial field, is widely used in industries such as gold mining, electroplating, and pharmaceuticals. However, its high toxicity and strong corrosiveness make it a high-risk chemical. How can we safely procure, transport, and use Sodium Cyanide under the premise of compliance? This article will provide you with professional guidance from a full-process perspective to help you avoid risks and ensure production safety.

I. Procurement of Sodium Cyanide

1. Clarify the Procurement Purpose and Eliminate Illegal Uses

Sodium cyanide is a highly toxic chemical strictly controlled by the state. Legal use is the primary prerequisite for procurement. For example:

Gold Mining: Used in the cyanidation leaching process for gold extraction;

Electroplating Industry: As a metal surface treatment agent;

Laboratory Research: Used in specific chemical experiments.

Key Steps:

Provide enterprise qualification certificates (business license, production license, etc.);

Submit a detailed description of the use and quantity plan;

Accept the compliance review of relevant departments.

2. Screen Legitimate Suppliers and Control Risks at the Source

It is crucial to select formal suppliers with a hazardous chemicals business license. You can screen through the following channels:

Authoritative Platforms: Such as the China Chemicals Trading Center and e-commerce platforms for hazardous chemicals;

Industry Recommendations: Consult peers or industry associations to obtain a list of reliable suppliers.

Verification Points:

Supplier qualification documents (business license, safety certification, etc.);

Product quality standards (such as the GB19268—2023 Specification for the Packaging of Solid Cyanides).

3. Preparation of Application Materials: Details Determine Success or Failure

The approval requirements for the Procurement of Sodium Cyanide vary slightly in different regions, but the following materials are usually required to be submitted:

Purchase application (including use, quantity, storage conditions);

Enterprise safety management system and emergency response plan;

Chemical safety training certificates for operators.

II. Transportation of Sodium Cyanide

1. Transportation Tools and Packaging Specifications

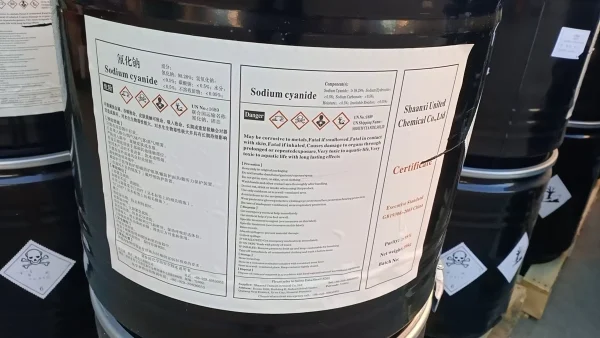

Solid Sodium Cyanide: Use a sealed van. The packaging should comply with the GB19268—2023 standard, and warning labels such as "highly toxic" and "corrosive" should be marked;

Liquid Sodium Cyanide: Use a special tank truck. The container should be pressure-resistant and leak-proof, and be equipped with an emergency cut-off device.

2. Transportation Safety Measures

Vehicle Identification: Hang the hazardous goods transportation sign and install a GPS positioning system;

Personnel Allocation: Supervised by a certified escort throughout the journey, and single-person transportation is prohibited;

Route Planning: Avoid densely populated areas and water source protection areas, and drive according to the specified time.

3. Emergency Response Plan: Be Prepared for Emergencies

Leakage Treatment: Evacuate the crowd immediately, cover it with sand or soda ash, and do not touch it directly;

Fire Response: Use a dry powder fire extinguisher and avoid mixing with nitrates and acids;

Regular Drills: Organize a transportation accident simulation drill once a quarter to improve emergency response capabilities.

III. Technical Guidance for Sodium Cyanide: Safe Use and Accident Response

1. Personal Protection and Operation Specifications

Protective Equipment: Wear a one-piece anti-toxic suit, rubber gloves, and a full-face anti-toxic mask;

Operation Process:

Accurately measure the dosage to avoid waste;

Thoroughly clean the equipment after operation to prevent residues;

It is prohibited to eat, drink, or smoke in the operation area.

2. Emergency Handling of Accidents

Personnel Poisoning:

Transfer to a ventilated place immediately and keep the respiratory tract unobstructed;

Inject 3% sodium nitrite (10-15ml) + 25% glucose solution (40ml);

Subsequently inject 50% sodium thiosulfate (20-50ml) for detoxification.

Environmental Leakage:

Seal off the site and neutralize acidic substances with lime;

Collect the leaked substances and entrust a professional institution for disposal.

Conclusion

The procurement, transportation, and use of sodium cyanide are systematic projects that need to run through the concept of "prevention first, combination of prevention and control". Through strict qualification review, standardized operation, and emergency preparedness, enterprises can not only give full play to the industrial value of Sodium cyanide but also minimize safety risks to the greatest extent.

- Random Content

- Hot content

- Hot review content

- Sulphuric Acid 98% Industrial Grade

- Company product introduction

- Industrial Acetic Acid 99.5% Colorless Liquid Glacial acetic acid

- Food Grade Heavy Light Precipitated Calcium Carbonate Powder Granular 99%

- Food Grade Ammonium Sulphate

- Pharmaceutical Grade Zinc Acetate

- Maleic Anhydride - MA

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 3Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Oxalic acid for mining 99.6%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3Zinc chloride ZnCl2 for High Molecular Weight Polymers Initiator

- 4High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 5High Quality Sodium Ferrocyanide / Sodium Hexacyanoferr

- 6Gold Ore Dressing Agent Safe Gold Extracting Agent Replace Sodium Cyanide

- 7Sodium Cyanide 98%+ CAS 143-33-9

Online message consultation

Add comment: