Introduction

Sodium cyanide (NaCN), a highly toxic inorganic salt, has played a pivotal role in industries ranging from mining to pharmaceuticals. This article traces its historical roots, explores its industrial evolution, and examines its current place in a sustainability-focused era.

1. Historical Origins

Sodium cyanide was first synthesized in the mid-19th century, initially gaining prominence as a reagent for metal processing and extraction. Its breakthrough came in the gold mining sector, where it became indispensable for separating gold and silver from ore through the cyanidation process.

By the late 1800s, industrialization expanded its use to:

Dye production

Synthetic rubber manufacturing

Pesticide development

2. 20th-Century Evolution

While Sodium Cyanide’s toxicity necessitated strict safety protocols, its utility drove widespread adoption:

Key Applications

Mining: Remained the dominant use case for gold extraction, enabling efficient recovery from low-grade ores.

Organic Chemistry: Served as a catalyst or intermediate in reactions like nitrile synthesis.

Pharmaceuticals: Used in the production of drugs like acetazolamide (a diuretic).

Regulatory Concerns Emerge

Growing awareness of its environmental and health risks led to:

Legislation: Countries like the U.S. and Canada enforced stricter regulations on storage, transportation, and disposal.

Industry Standards: Adoption of safety frameworks to minimize accidental exposure.

3. Current Landscape (21st Century)

Today, sodium cyanide’s role is shaped by sustainability goals and technological innovation:

1. Alternative Technologies

Green Mining: Research into non-toxic substitutes (e.g., thiosulfate leaching) aims to reduce reliance on cyanide.

Biodegradable Alternatives: Development of eco-friendly chelating agents for metal extraction.

2. Stricter Regulations

Global Compliance: Nations enforce ISO 14001 and REACH-like standards to mitigate environmental harm.

Digital Tracking: Blockchain and IoT tools improve supply chain transparency.

3. Research and Education

Safety Training: Mandatory programs for industrial workers handling NaCN.

Academic Initiatives: Universities partner with industries to explore safer synthesis methods.

Conclusion

From its 19th-century discovery to its modern-day applications, Sodium cyanide remains a paradox: a vital industrial tool with inherent risks. While alternatives and regulations strive to reduce its ecological footprint, its irreplaceable role in sectors like mining ensures its continued use—albeit with a sharper focus on safety and sustainability.

- Random Content

- Hot content

- Hot review content

- Flexible Customer and Supplier Relations Specialist (Location: India)

- Flexible Customer and Supplier Relations Specialist (Location: Nigeria)

- Ferrous Sulfate Industrial Grade 90%

- Anhydrous Ammonia 99% Liquid

- butyl vinyl ether

- Isobutyl vinyl ether 98% high purity certified Professional producer

- 99% Animal Feed Additive DL Methionine

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

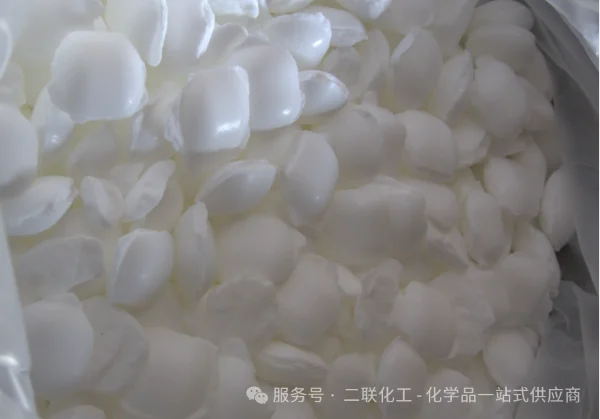

- 3Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Oxalic acid for mining 99.6%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3Zinc chloride ZnCl2 for High Molecular Weight Polymers Initiator

- 4High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 5High Quality Sodium Ferrocyanide / Sodium Hexacyanoferr

- 6Gold Ore Dressing Agent Safe Gold Extracting Agent Replace Sodium Cyanide

- 7Sodium Cyanide 98%+ CAS 143-33-9

Online message consultation

Add comment: