Mayskoye Gold Mine

The Mayskoye gold mine, situated in the Chukotka region of Russia, is a significant gold - bearing site with complex geological characteristics. The ore body is an intricate mineralized breccia zone. It is composed of quartz veins that are interspersed within argillaceous altered rocks. These quartz veins are the main hosts of gold, and their formation is closely related to the complex tectonic and hydrothermal activities in the region.

There are two principal ore types: the primary ore, which is highly refractory. This refractory nature is mainly due to the fine - grained dissemination of gold within sulfide minerals, such as pyrite and arsenopyrite. These minerals encapsulate the gold particles, making it extremely difficult to extract the gold using conventional methods. The oxidized ore, on the other hand, is mainly composed of quartz mica. Along with quartz mica, there are minor amounts of feldspar, kaolin, and sulfides. The oxidation process has altered the mineralogy of the ore, which in turn affects the gold - extraction process.

For the processing of oxidized ore, it is directed to a CIL (Carbon - in - Leach) plant. When the oxidized ore samples were initially processed in the CIL plant, the gold recovery rate was disappointingly low. This was primarily attributed to the "preg - roasting" effect of organic matter present in the ore. The organic matter has a strong affinity for gold cyanide complexes, effectively "stealing" the gold from the leaching solution. To counter this issue, a two - step process was implemented. First, flotation of carbon - containing substances was carried out. In this flotation process, collectors and frothers were carefully selected and adjusted to selectively separate the carbon - bearing materials from the rest of the ore. After the flotation, the flotation tailings were then subjected to leaching. This approach reduced the "preg - roasting" phenomenon by three times. As a result, the gold recovery rate significantly improved, reaching levels that made the extraction process economically viable.

Regarding the primary ore, approximately 90% of the gold is recovered through flotation. The flotation process involves the use of various reagents, including collectors, frothers, and modifiers. These reagents are carefully optimized to target the sulfide minerals that host the gold. The obtained sulfide concentrate, rich in gold and sulfide minerals, is then transported over a long distance to a plant in the Amur region. At this plant, the concentrate undergoes oxidation, which is a crucial step to break down the sulfide minerals and release the encapsulated gold. After oxidation, cyanide tank leaching is carried out. The cyanide solution reacts with the gold, forming soluble gold - cyanide complexes that can be further processed to recover the gold.

Gold Mine Waste Heap Leaching

In Russian gold - mining enterprises, the waste heaps are a valuable source of secondary gold recovery. These waste heaps are the by - products of previous mining and processing operations. They contain a substantial amount of gold, which was not fully recovered during the initial extraction processes. The gold in the waste heaps is often present in various forms, including fine - grained gold particles, gold - bearing minerals, and gold adsorbed on the surface of other minerals.

Research indicates that the leaching rate of gold from these waste heaps by percolation cyanidation can reach 75% - 82%. Percolation cyanidation is a process where a dilute cyanide solution is sprayed or trickled onto the waste heap. The cyanide solution percolates through the waste heap, reacting with the gold and forming soluble gold - cyanide complexes. These complexes are then collected at the bottom of the waste heap for further processing.

However, due to the low fineness of the mineral structure in the waste heaps, there are several challenges. The low - fineness minerals result in slow percolation of the working solution. This means that the cyanide solution takes a long time to penetrate through the waste heap, reducing the overall efficiency of the leaching process. Additionally, preventing the static damage of the waste heap is a major concern. The weight of the waste heap and the chemical reactions during leaching can cause the waste heap to collapse or become unstable. To address these issues, some studies suggest granulating the waste heaps. One method is hot - air pre - drying, where the waste heap is dried using hot air to improve its permeability. Another method is mixing the waste heap with ore in a certain proportion. This mixture can improve the structure of the waste heap, making it more conducive to the percolation of the leaching solution and enhancing the stability of the waste heap.

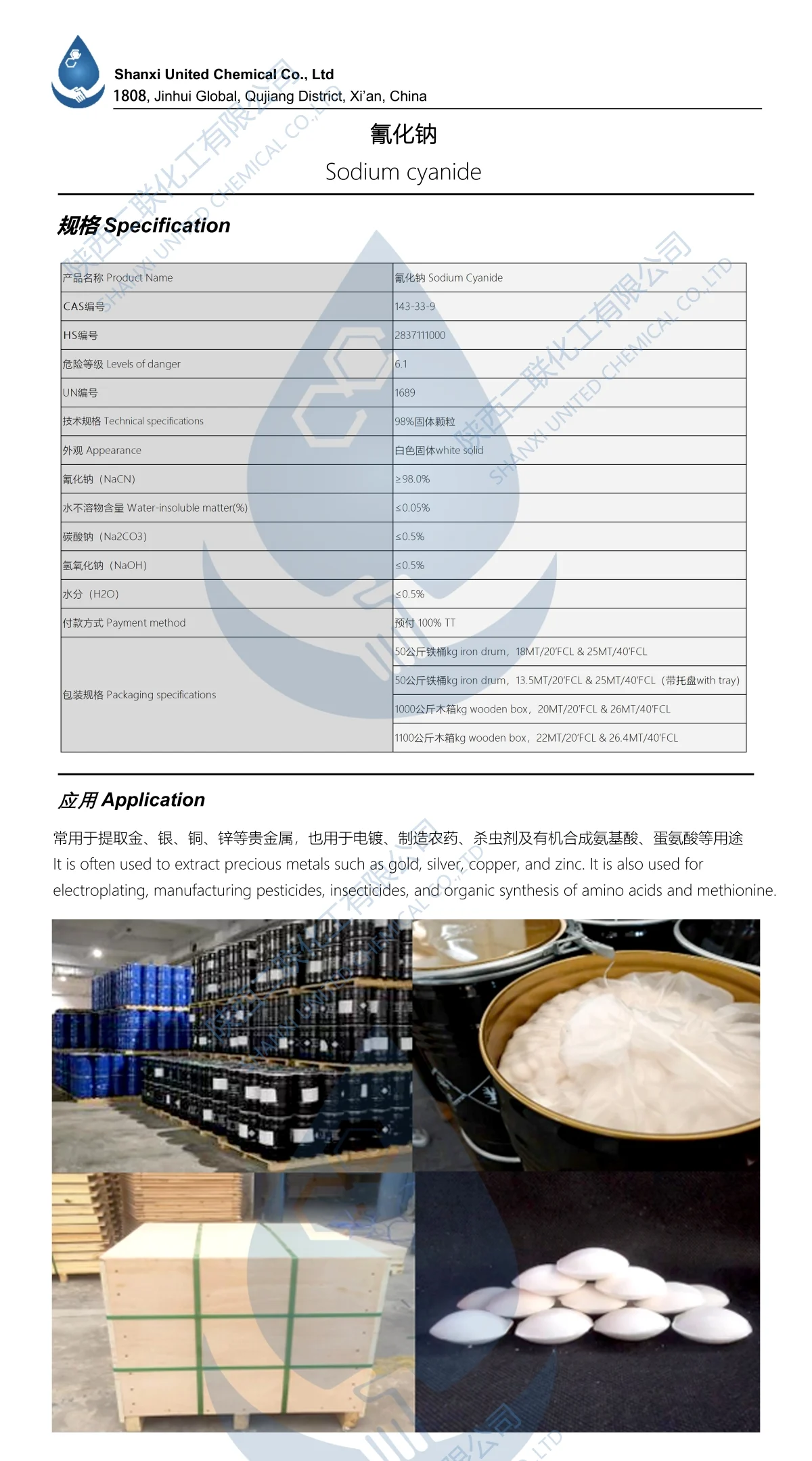

Shaanxi United Chemical: Your Ideal Partner

This company offers sodium cyanide with both low - price and high - quality. Sodium cyanide is a key reagent in the gold leaching process. The cost - effective sodium cyanide provided by Shaanxi United Chemical helps the mine to reduce production costs while ensuring high - quality leaching results. Moreover, the company doesn't just stop at product supply. It provides comprehensive technical support to the mine. This includes professional advice on the optimal dosage of sodium cyanide according to different ore characteristics, guidance on the safe storage and handling of sodium cyanide, and assistance in setting up efficient leaching systems.

- Random Content

- Hot content

- Hot review content

- Reagent Grade/Industrial Grade Hydrochloric Acid min.31%

- Industrial concentrated nitric acid 55%-68%

- High-strength, High-precision Shock Tube Detonator

- Potassium Permanganate – Industrial Grade

- Sodium Peroxide

- Anhydrous Ammonia 99% Liquid

- Hydrogen Peroxide

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 3Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Oxalic acid for mining 99.6%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3Zinc chloride ZnCl2 for High Molecular Weight Polymers Initiator

- 4High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 5High Quality Sodium Ferrocyanide / Sodium Hexacyanoferr

- 6Gold Ore Dressing Agent Safe Gold Extracting Agent Replace Sodium Cyanide

- 7Sodium Cyanide 98%+ CAS 143-33-9

Online message consultation

Add comment: