In order for us to understand whether our Sodium cyanide is compatible with your Mining process, we need the following information from you:

1. Types of Ores

1.Oxidized ores

This type of ore has undergone oxidation and usually contains minerals such as iron oxide. Oxidized ores are generally easier to process than Primary ores because their state has changed, which usually can improve the leaching efficiency.

2.Primary ores

Primary ores, also known as unOxidized ores, have not undergone significant chemical changes. Primary ores usually contain sulfide minerals and are more difficult to process, requiring more intensive and complex leaching techniques.

3.Others (please specify)

If the type of your ore does not fall into the above categories, please provide specific details. This may include mixed ores, refractory ores, or any other unique characteristics that may affect the processing and leaching efficiency. Describing the specific mineral composition and geological features will help us better understand the type of your ore and recommend the most appropriate processing method.

2. Average Gold Grade of the Raw Ore

Please provide the average concentration of gold in the raw ore, usually expressed in grams per ton (g/t). This information is crucial because it determines the efficiency and cost - effectiveness of the leaching process. The higher the Gold grade, the more profitable the mining process will be. On the other hand, a lower gold grade may require more advanced technologies to achieve the best recovery rate. Understanding the gold grade helps us customize the dosage of sodium cyanide and the technological process to maximize the recovery of gold from a specific type of ore.

3. Spectral Analysis Report of the Ore's Material Composition

Do you have a spectral analysis report of the ore's material composition? If so, please attach it or summarize the main findings.

4. Leaching Technology Adopted

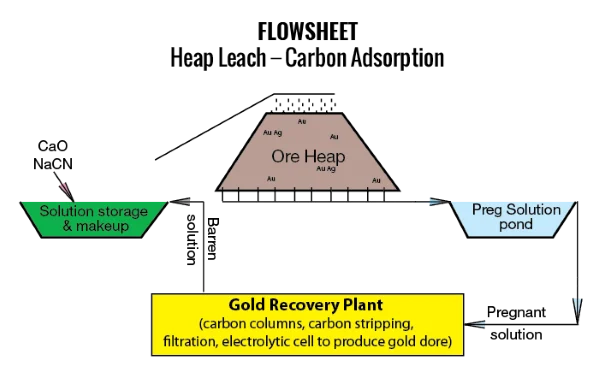

1.Heap leaching

It is a process in which gold ores are piled up and rinsed with a leaching solution to dissolve the precious metals. It is suitable for low - grade ores and is usually used in large - scale operations due to its cost - effectiveness.

If Heap leaching, please specify the following items:

Ore processing capacity (tons per day/month/year)

Average particle size (mesh or mm)

Size of the ore heap (height, thickness)

Current leaching rate (recovery rate %) using NaCN

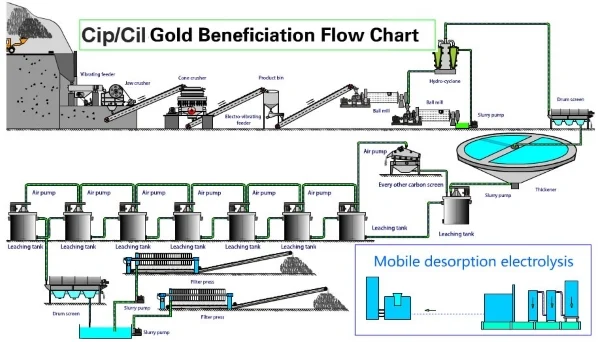

2.CIL (Carbon in Leach)

It involves leaching a gold ore pulp with a sodium cyanide solution and simultaneously adsorbing it onto activated carbon. This is an efficient method for recovering gold from high - grade ores and is commonly used in modern gold processing plants.

If CIL/CIP leaching, please specify the following items:

Ore processing capacity (tons per day/month/year)

Crushing fineness (mesh or mm)

Slurry concentration (% solids)

Current leaching rate (recovery rate %) using NaCN

3.CIP (Carbon in Pulp)

It is similar to CIL, but the gold is first leached and then adsorbed onto activated carbon in a separate tank. This method is also effective for high - grade ores and can provide better control over the leaching and adsorption stages.

4.Others (please specify)

If your Leaching technology is different from the above, please provide detailed information. This may include alternative methods such as bioleaching, thiosulfate leaching, or other innovative technologies. Providing specific information will help us plan a feasible solution and recommend appropriate adjustments if necessary.

Providing this information will help us customize solutions according to your specific needs and ensure that sodium cyanide performs optimally in your operations. Thank you for your cooperation!

We provide the best gold ore dressing agent, sodium cyanide, achieving the highest efficiency and environmental protection. Our sodium cyanide undergoes a strict production process, which can improve the gold recovery rate while minimizing the impact on the environment, ensuring the extraction of gold in a sustainable manner.

If you have chemical product needs, please contact us immediately: United Chemical

- Random Content

- Hot content

- Hot review content

- Shock Tube Detonator

- Sodium Peroxide

- Barium carbonate 99% powder

- Food Grade Heavy Light Precipitated Calcium Carbonate Powder Granular 99%

- Phthalic anhydride

- 97% 2-Hydroxypropyl methacrylate

- Diethylene Glycol

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Sodium Hydroxide,Caustic Soda Flakes,Caustic Soda Pearls 96%-99%

- 5Nutritional Supplements Food Addictive Sarcosine 99% min

- 6Sodium Cyanide Import Regulations & Compliance – Ensuring Safe and Compliant Importation in Peru

- 7United Chemical's Research Team Demonstrates Authority Through Data-Driven Insights

Online message consultation

Add comment: