Product Overview

Product Name: Zinc Chloride

CAS Number: 7646-85-7

Molecular Formula: ZnCl₂

Molecular Weight: 136.3 g/mol

Purity: Typically ≥99%, with customizable specifications to meet client needs.

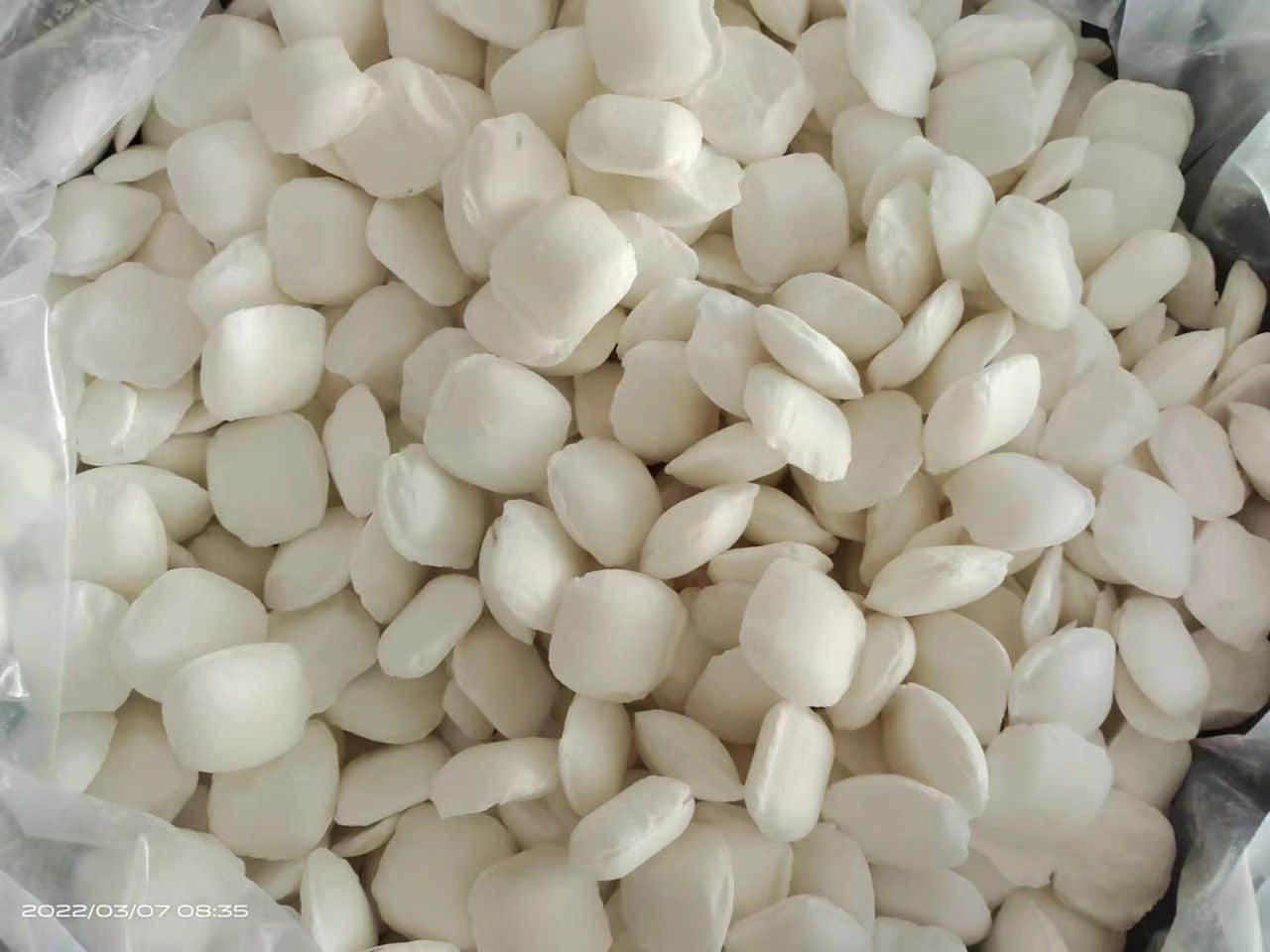

Physical Form: White solid, highly water-soluble, and hygroscopic.

For more detailed information on Zinc Chloride (CAS: 7646-85-7), including specifications, packaging options, and availability, please visit our Zinc Chloride product page. Our team is ready to assist with any specific requirements or questions you may have regarding this product.

Procurement and Transaction Process

Contract: Once the order is confirmed, a formal contract is signed detailing product specifications, quantity, and pricing.

Payment Options: Flexible payment arrangements are available, including T/T (wire transfer), L/C (letter of credit), and other secure methods.

Production & Preparation: Production and stock preparation begin as soon as the contract is signed, ensuring timely delivery.

Transportation: For domestic orders, we provide our own hazardous materials transportation fleet, while for international shipments, we collaborate with experienced logistics companies to ensure safe and efficient transit.

Delivery: Global delivery services are available, guaranteeing safe, timely arrival of products worldwide.

Manufacturing Process & Raw Materials

Zinc chloride is typically produced through two main methods:

Direct Reaction Method: Chlorine gas reacts directly with zinc metal to produce Zinc Chloride, often used in industrial-grade production.

Zinc Ore Extraction: Zinc chloride can also be obtained by acid treatment and concentration of zinc ores, particularly for higher-purity products.

These processes allow us to control the purity and impurity content to suit various industrial requirements.

Industry Applications and Uses

As a key industrial chemical, zinc chloride is widely used in diverse industries, including:

Metalworking and Electroplating

Usage: Acts as an additive in electroplating, especially in cleaning and pre-treatment of steel and galvanized layers, effectively removing oxidation layers.

Benefits: High-purity zinc chloride enhances plating quality and improves corrosion resistance.

Metallurgy and Mineral Processing

Usage: Functions as a collector or inhibitor in mineral flotation, assisting in the separation of valuable metals from ore.

Benefits: Zinc chloride’s selective inhibition enables effective mineral separation, especially in copper and zinc ore flotation.

Chemical Synthesis and Pharmaceuticals

Usage: Used as a catalyst in synthesizing pharmaceuticals and organic chemicals, boosting reaction efficiency.

Benefits: Essential in pharmaceutical and fine chemical production, zinc chloride serves as a key raw material for various drugs and reagents.

Water and Wastewater Treatment

Usage: Acts as a coagulant and precipitant in water treatment, effectively removing impurities and pollutants.

Benefits: Zinc chloride enhances treatment effectiveness, suitable for purifying municipal and industrial wastewater.

Chemical Reagents

Usage: Widely used as a reagent in laboratories for analysis, desiccation, and other applications.

Benefits: High-purity zinc chloride exhibits stable properties and strong hygroscopicity, ideal for precise analytical needs.

Product Packaging and Specifications

Packaging Options: Available in bags, drums, and bottles in various sizes.

Packaging Specifications: Standard sizes of 25 kg, 50 kg, or bulk ton bags can be customized based on customer needs, ensuring convenient and safe transport.

Storage Safety: Zinc chloride must be sealed in cool, dry storage to avoid direct contact with moisture, preventing hygroscopic reaction.

Product Quality and Standards

We provide zinc chloride in multiple quality grades to cater to different industry requirements:

Industrial Grade: Suitable for general industrial applications such as surface treatment and mineral flotation.

Pharmaceutical Grade: Meets higher purity standards, ideal for pharmaceutical and fine chemical production.

Electronic Grade: For applications requiring high purity, such as electroplating and semiconductor manufacturing.

Competitive Advantages

High-Purity Options: Our zinc chloride products have a purity of ≥98%, meeting the diverse needs of multiple industries.

Customizable Service: We offer tailored zinc chloride products of various specifications and purities, allowing flexible choices for each client’s specific industry requirements.

Stable Supply Chain: With warehouses and supply bases in Southeast Asia and other regions, we ensure ample zinc chloride availability and reduced lead times.

Technical Support: Our professional technical team provides guidance to ensure optimal product performance across various applications.

Service Features

At United Chemical, our clients benefit from a streamlined, one-stop service model featuring expertise, customizable solutions, and efficient global logistics. Additionally, we enhance client experience through global technical support, consultation, product discounts, and a range of value-added services to maximize customer satisfaction.

Safety and Environmental Considerations

Zinc chloride is a hazardous chemical, and proper safety measures must be observed:

Safety Precautions: Operators should wear necessary protective gear to avoid direct skin contact.

Storage Requirements: Due to zinc chloride’s hygroscopic nature, it should be stored in a sealed environment, protected from moisture.

Waste Disposal: Follow local environmental regulations for zinc chloride waste disposal to minimize environmental impact.

Contact Information

United Chemical Co., Ltd.

Email: info@unitedchemicalcn.com

TEL/WhatsApp: +86 17392705576

Website: www.unitedchemicalcn.com

With United Chemical’s professional team and commitment to service, our clients experience the reliability, quality, and safety they expect from a global leader in industrial chemical supply.

- Random Content

- Hot content

- Hot review content

- The Essential Guide to Sodium Cyanide: Usage Cases and Sourcing

- Oxalic acid for mining 99.6%

- Expanded AN explosive

- Potassium Permanganate – Industrial Grade

- Lithium chloride, 99.0%,99.5%

- 97% 2-Hydroxypropyl methacrylate

- Adipic acid 99% used as the material of nylon 66

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 3Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Oxalic acid for mining 99.6%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3Zinc chloride ZnCl2 for High Molecular Weight Polymers Initiator

- 4High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 5High Quality Sodium Ferrocyanide / Sodium Hexacyanoferr

- 6Gold Ore Dressing Agent Safe Gold Extracting Agent Replace Sodium Cyanide

- 7Sodium Cyanide 98%+ CAS 143-33-9

Online message consultation

Add comment: