In the surging wave of the booming global gold mine industry, Kazakhstan occupies a pivotal position with its rich gold mine resources. Now, with full enthusiasm and sincerity, we bring professional gold leaching chemicals - Sodium Cyanide, as well as comprehensive Technical Services, looking forward to marching side by side with gold mine enterprises in Kazakhstan and jointly opening up a new chapter in gold mine exploitation and extraction.

I. In - depth Analysis of the Technical Principle of Cyanide Gold Extraction

The Cyanide Gold Extraction process is widely applied in the gold mine extraction field, based on its unique and exquisite chemical reaction mechanism. When sodium cyanide (NaCN) solution comes into contact with gold ore, a series of complex and orderly reactions occur quietly.

Firstly, in an aerobic environment, Sodium cyanide undergoes weak hydrolysis in water to produce cyanide ions (CN⁻). With the participation of oxygen in the air, gold undergoes a complexation reaction with cyanide ions. The chemical reaction equation is: 4Au + 8NaCN + O₂ + 2H₂O = 4NaAu(CN)₂ + 4NaOH. In this reaction, gold is oxidized to monovalent gold ions (Au⁺) and forms a stable complex - sodium dicyanoaurate (NaAu(CN)₂) with cyanide ions, thus making gold dissolve in the solution.

Next, the gold dissolved in the solution needs to be extracted. One of the commonly used methods is the zinc powder replacement method. When zinc powder (Zn) is added to the solution containing sodium dicyanoaurate, due to the stronger metal activity of zinc than that of gold, the following replacement reaction occurs: 2NaAu(CN)₂ + Zn = 2Au + Na₂Zn(CN)₄. In this process, the gold ions in the solution are replaced by zinc and precipitate in the form of elemental gold, thus achieving the extraction of gold.

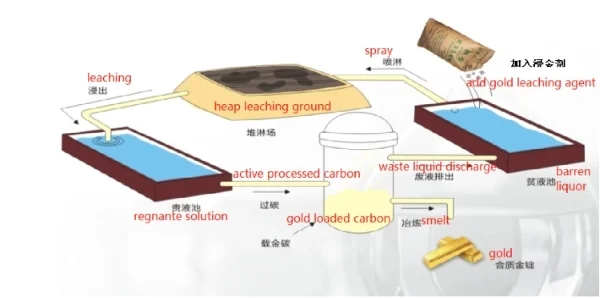

Another commonly used method is the activated carbon adsorption method. Activated carbon has a huge specific surface area and rich microporous structure, and has a strong adsorption capacity for dicyanoaurate ions (Au(CN)₂⁻). When the solution containing gold complexes passes through the activated carbon bed, the gold complexes are adsorbed on the surface of the activated carbon. Then, through subsequent processes such as desorption and electrolysis, gold is separated from the activated carbon to obtain high - purity gold.

II. The Advantages of the Cyanide Gold Extraction Process are Evident

1. Significant Cost Advantage

As a key chemical in the cyanide gold extraction process, the price of sodium cyanide is relatively stable and its cost can be controlled in large - scale production. This enables gold mine enterprises to effectively control extraction costs during long - term production and operation, and improve economic benefits. Compared with some other expensive reagents required by other gold extraction processes, the Cost Advantage of sodium cyanide is self - evident, reducing the financial pressure on enterprises and enhancing their market competitiveness.

2. Extremely High Gold Extraction Efficiency

The cyanide gold extraction process has a very strong dissolving ability for gold and can fully extract gold from ore. Under appropriate process conditions, the gold recovery rate can reach a relatively high level, which means that enterprises can obtain more gold from the same amount of ore, greatly improving resource utilization rate and creating more value for enterprises.

3. Mature and Stable Process

After years of development and practice, the cyanide gold extraction process has become quite mature. Its operation process is standardized and technicians can easily master it. This enables gold mine enterprises to operate more stably and efficiently during the production process, reducing production accidents and losses caused by technical instability and lowering production risks.

4. Wide Adaptability

This process has good adaptability to different types of gold ores. Whether it is oxidized ore, sulfide ore or mixed ore, effective gold extraction can be achieved by reasonably adjusting process parameters. This Wide Adaptability enables gold mines with various geological conditions in Kazakhstan to adopt the cyanide gold extraction process and give full play to their resource advantages.

III. All - round Technical Services Escort

Our company deeply understands that high - quality products are only the foundation of cooperation, and all - round technical services are the key to ensuring the smooth production of gold mine enterprises. Therefore, we have formed a technical team composed of senior experts to provide one - stop technical support for gold mine enterprises in Kazakhstan.

In the early stage of the project, our technical team will conduct in - depth on - site geological surveys and ore analyses in gold mines, and through beneficiation tests, customize the most suitable gold extraction process plans for enterprises to ensure the feasibility and high efficiency of the process.

During the production process, our technical personnel will provide full - track guidance, and promptly solve problems encountered by enterprises in equipment debugging, operation processes, and process parameter control. We will also regularly provide professional training for the technical and operating personnel of enterprises to help them continuously improve their technical levels and operating skills, ensuring the stable operation of the production process.

In terms of later equipment maintenance, we have a professional equipment maintenance team that can provide enterprises with services such as regular equipment inspections, maintenance, and troubleshooting, ensuring that the equipment is always in good operating condition, extending the service life of the equipment, and reducing the equipment maintenance costs of enterprises.

Dear gold mine enterprise friends in Kazakhstan, we sincerely invite you to cooperate with us. Choosing our sodium cyanide products and technical services means choosing professionalism, high efficiency, and peace of mind. Let's show our talents in the gold mine field, jointly create more brilliant achievements, and contribute to the development of the gold mine industry in Kazakhstan!

- Random Content

- Hot content

- Hot review content

- Unlocking the Power of Mineral Processing Chemicals: Enhancing Efficiency and Sustainability

- Collector BLK-301/Composite Flotating Active Matter ≥60%

- High-strength Shock tube(VOD≧2000m/s)

- Sodium Metal, ≥99.7%

- Potassium Permanganate – Industrial Grade

- Antimonium Tartrate Potassium

- Feed Grade 98.0% Calcium Formate

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 3Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Oxalic acid for mining 99.6%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3Zinc chloride ZnCl2 for High Molecular Weight Polymers Initiator

- 4High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 5High Quality Sodium Ferrocyanide / Sodium Hexacyanoferr

- 6Gold Ore Dressing Agent Safe Gold Extracting Agent Replace Sodium Cyanide

- 7Sodium Cyanide 98%+ CAS 143-33-9

Online message consultation

Add comment: