In the field of gold extraction and processing, the use of Sodium Cyanide to dissolve gold is a well - known method. Sodium cyanide, in which the (CN)₂ component is often referred to as a pseudohalogen due to its similar properties to halogens, along with substances like (SCN)₂, is introduced in a specific section of the "Inorganic Chemistry" course at the university level. Structurally and in terms of properties, NaCN can be analogized to NaCl, and it belongs to the category of inorganic compounds.

The General Process of Dissolving Gold with Sodium Cyanide

The process of using sodium cyanide to dissolve gold typically involves maintaining a pH range of 11 - 12. Adding a small amount of hydrogen peroxide is also part of the procedure. The gold - containing material needs to be soaked for several days. Subsequently, zinc wire is used for reduction. It should be emphasized that the used solution is highly toxic and must be treated with sodium hypochlorite for oxidation to render it less harmful.

There are two main methods for cyanide leaching of gold: Percolation Cyanide Leaching and Agitation Cyanide Leaching.

Percolation Cyanide Leaching

Percolation cyanide leaching includes tank leaching and heap leaching. Tank leaching in percolation is often used to treat gold - bearing sands and relatively coarse - grained calcines with a particle size of - 3 + 0mm. When conducting heap leaching for low - grade gold - bearing ores, depending on the particle size of native gold dissemination and the porosity of the ore, the ore is usually crushed to less than 50mm (or 10mm) in advance. The smaller the particle size of the ore blocks, the higher the gold leaching rate. During percolation cyanide leaching, the concentration of Sodium cyanide is usually 0.03% - 0.2%. The indicators of percolation cyanide leaching depend on factors such as the particle size of gold, the content of sulfides, the particle size of ore blocks, the percolation rate, the leaching time, the concentration of cyanide agents, and the degree of washing of the leaching residue. When treating gold - bearing quartz sands, the gold leaching rate can reach 85% - 90%; when the particle size is coarse, the gold leaching rate drops to 60%. During percolation cyanide heap leaching, the gold content in the pregnant solution is low, and generally, activated carbon adsorption is required for enrichment. Gold is extracted from the pregnant solution obtained from the desorption of gold - loaded carbon by electrowinning or zinc replacement.

Agitation Cyanide Leaching

Agitation cyanide leaching is often used to leach gold - bearing mineral raw materials with a particle size of less than 0.3mm. The leaching process takes place in a compressed - air agitation tank, a mechanical agitation tank, or a combined agitation tank. The leaching process includes operations such as solid - liquid separation of the pulp, counter - current washing, zinc powder replacement of the pregnant solution, and smelting of gold mud. The concentration of the leached pulp is generally less than 30% - 33%. When the content of slime is high, the concentration of the leached pulp should be less than 22% - 25%. During operation, lime is added to adjust the pH of the pulp to 9 - 12. Air is charged to maintain the optimal ratio between the dissolved oxygen concentration and the sodium cyanide concentration in the pulp. The concentration of sodium cyanide in the pulp is usually 0.02% - 0.1%. Most concentrators using the agitation cyanidation process adopt the washing method to separate the pregnant solution and the leaching residue. The washing methods can be divided into decantation, filtration, and fluidized - bed washing. The most commonly used method is the continuous counter - current decantation method (CCD method). The thickeners used in this method can be divided into single - layer and multi - layer types. Many cyanide concentrators in China use 2 - 3 - layer thickeners for solid - liquid separation and continuous counter - current washing. The obtained pregnant solution is clarified, filtered, and deoxygenated before being sent for zinc powder replacement. The obtained gold mud is smelted to obtain dore (gold - silver alloy).

The Role of Alkaline Pretreatment

Adding sodium hydroxide for alkaline pretreatment can weaken or eliminate the influence of harmful elements in the ore, improve the leaching environment, and achieve better leaching results. Minerals such as pyrite, sphalerite, and chalcopyrite present in the ore sample can produce harmful ions such as Fe²⁺, Fe³⁺, S²⁻, and Cu²⁺. If no alkali - addition pretreatment is carried out, these harmful ions will consume a large amount of cyanide and dissolved oxygen during cyanide leaching, seriously hindering the dissolution of gold and resulting in a decrease in the gold leaching rate. During alkali - addition pretreatment, Cu²⁺ and Zn²⁺ form insoluble hydroxide precipitates, and S²⁻ is oxidized to form SO₃ and SO₄²⁻, reducing the consumption of cyanide. Fe(OH)₃ forms a surface protective film on the surface of minerals such as pyrite, preventing its rapid oxidation and further dissolution, thus reducing the consumption of CN⁻.

The Amount of Sodium Cyanide Required to Dissolve Gold

Statistical data indicates that approximately 100 - 300 grams of sodium cyanide are required to dissolve one gram of gold. This amount can vary depending on multiple factors such as the type of ore, the fineness of the gold particles, and the specific leaching method used.

In conclusion, while the use of sodium cyanide in Gold Dissolution is an effective method, it is crucial to pay attention to safety and environmental protection due to the toxicity of sodium cyanide. Stringent safety measures and proper treatment of waste solutions are essential to minimize the negative impacts on human health and the environment.

- Random Content

- Hot content

- Hot review content

- industry Electric Detonator

- Acetone

- 99.5% min Ammonium Chloride For Industrial Use

- Calcium Peroxide 60% Assay Yellowish Tablet

- Ferrous Sulfate Industrial Grade 90%

- Potassium borohydride

- Anhydrous Ammonia 99% Liquid

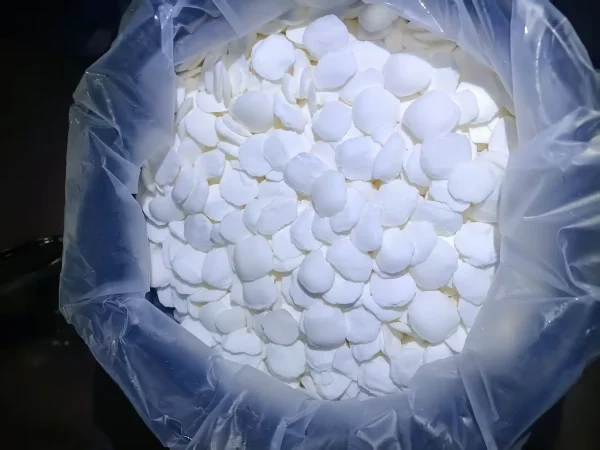

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Sodium Hydroxide,Caustic Soda Flakes,Caustic Soda Pearls 96%-99%

- 5Nutritional Supplements Food Addictive Sarcosine 99% min

- 6Sodium Cyanide Import Regulations & Compliance – Ensuring Safe and Compliant Importation in Peru

- 7United Chemical's Research Team Demonstrates Authority Through Data-Driven Insights

Online message consultation

Add comment: