Technical process

The raw materials of Columnar Activated Carbon are mainly Coal and Wood. The product is made through crushing, mixing, extrusion, molding, drying, Carbonization and activation. The current columnar activated carbon has lower ash content, less impurities and CTC is absolutely superior to traditional columnar carbon.

characteristic

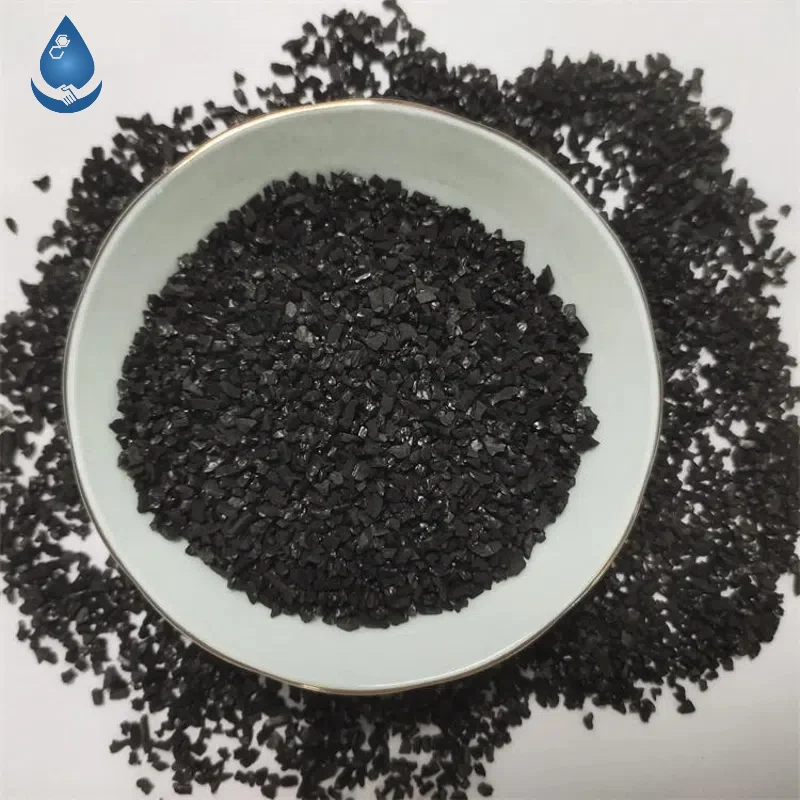

The appearance is Black Columnar Particles. It has the characteristics of developed porosity, large Specific Surface Area, strong Adsorption Capacity, high mechanical strength, easy repeated regeneration and low cost.

application

Pillar activated carbon is widely used in waste gas treatment, H2S removal, siloxane removal, volatile organic compound removal, desulfurization, and denitrification.

Solvent recovery, steam recovery, automotive carbon canister, gold recovery, water treatment, catalyst carrier

Technical Parameter

| Iodine value(mg/g) | 300-1100 |

| Particle diameter (mm) | Ф1.5mm、Ф2.0mm、Ф3.0mm、Ф4.0mm、 Ф6.0mm、Ф8.0mm |

| hardness (%) | ≥ 92 |

| carbon tetrachloride (%) | 10-100 |

| Benzene adsorption value(%) | 5-60 |

| humidity (%) | ≤5 |

| Ash(%) | ≤10 |

- Random Content

- Hot content

- Hot review content

- Industrial concentrated nitric acid 55%-68%

- Sodium Amyl Xanthate (SAX) 90%, Mining chemical, mining flotation reagent

- Collector BLK-301/Composite Flotating Active Matter ≥60%

- Sodium Peroxide

- Triethanolamine(TEA)

- Phosphoric Acid 85% (Food grade)

- Sodium sulphate 99% Pharmacy Grade

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Sodium Hydroxide,Caustic Soda Flakes,Caustic Soda Pearls 96%-99%

- 5Nutritional Supplements Food Addictive Sarcosine 99% min

- 6Sodium Cyanide Import Regulations & Compliance – Ensuring Safe and Compliant Importation in Peru

- 7United Chemical's Research Team Demonstrates Authority Through Data-Driven Insights

Online message consultation

Add comment: