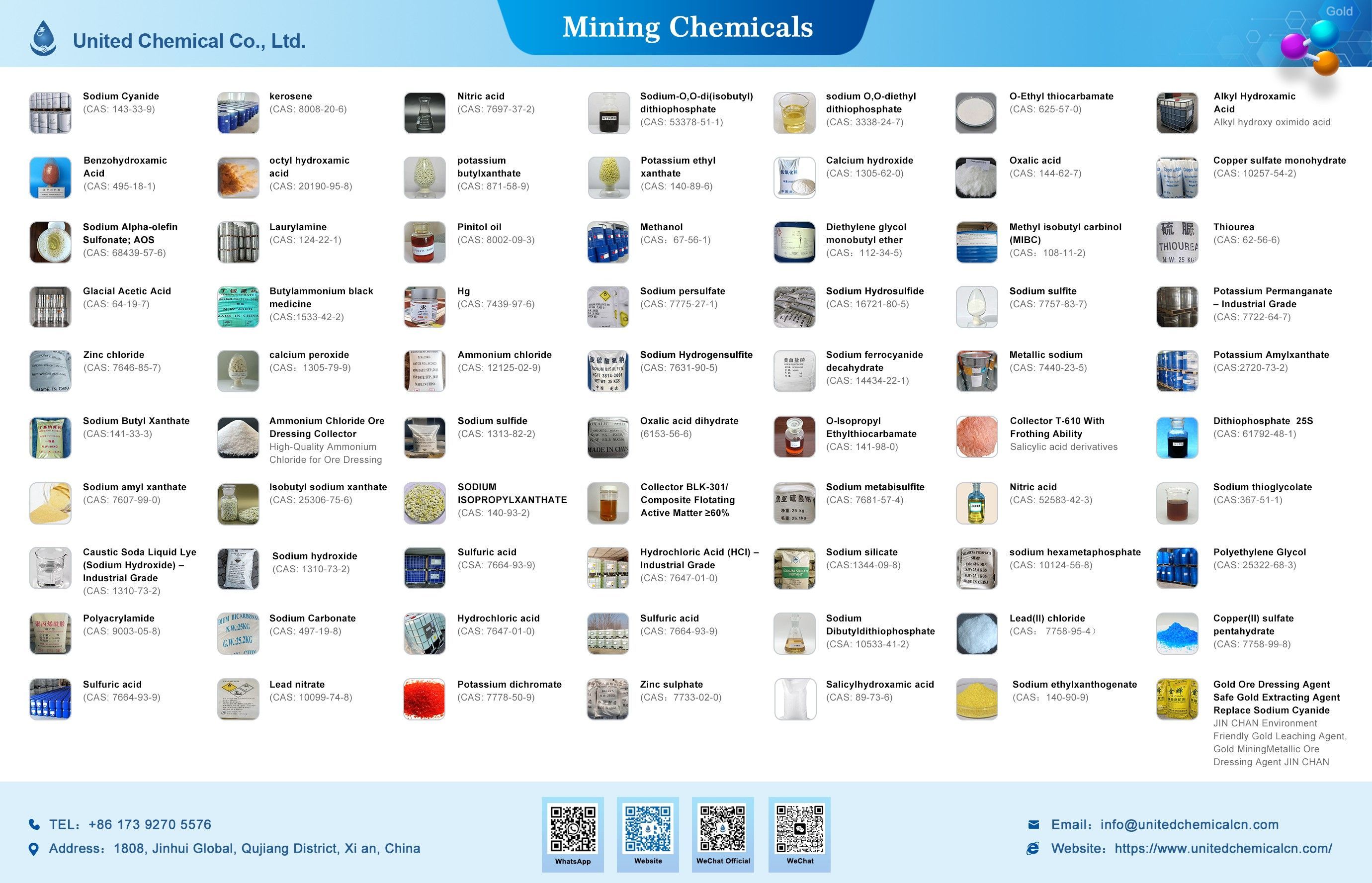

Shaanxi United Chemical Co., Ltd., as a high-quality mining chemical supplier trusted by global mining companies, focuses on providing comprehensive mineral processing reagent solutions for the global mining industry. Our product lines are rich and diverse, including yellow medicine series, black medicine series, sulfur and nitrogen series, frother series and flotation oil series. At the same time, we also tailor professional products for gold, silver, copper, lead, zinc, sulfur and other elements to meet the specific needs of customers. In addition, we provide efficient reagent solutions for difficult-to-treat ores such as high-carbon, high-arsenic, high-sulfur, high-oxidation, poor, complex and fine-grained minerals.

The company's flagship product, Sodium cyanide, has an annual production capacity of 50,000 tons. We have established a strong market influence in Southeast Asia, Africa, Eastern Europe and other regions, setting a benchmark for the industry. Our product lines are rich and diverse, including yellow medicine series, black medicine series, sulfur and nitrogen series, frother series and flotation oil series...

Our classification of mineral processing reagents

In order to explain the classification of mineral processing reagents in more detail, we briefly popularize the specific types of each reagent.

Collector

The collector is one of the most critical reagents in the mineral processing process. Its function is to make the surface of the target mineral hydrophobic so that it can attach to the bubbles and float out.

Frothing agent

The main function of the frother is to produce and stabilize the foam layer, thereby promoting the attachment and separation of mineral particles.

Depressant

Depressants are used to selectively inhibit the flotation of certain minerals, thereby separating them from the target minerals.

Activator

Activators are used to enhance the reactivity of the surface of certain minerals, making it easier to combine with collectors and improve their flotation efficiency.

pH regulator

The pH regulator is used to control the pH of the slurry, which directly affects the reagent activity and mineral reactivity during the flotation process.

Flocculant

Flocculants are used to aggregate fine mineral particles into larger particles for sedimentation or filtration, thereby accelerating the solid-liquid separation process.

Dispersants

Dispersants are used to prevent mineral particles from agglomerating and maintain uniform distribution of the slurry to improve flotation.

Floatation oil

The role of flotation oil is to help hydrophobic particles attach to bubbles during flotation and promote particle aggregation and separation.

Leaching agent

Leaching agents are mainly used in hydrometallurgy to leach metals from ores into solutions for further extraction.

Adjusting agent

Adjusting agents are used to control the surface characteristics of minerals and the action of reagents to ensure the selectivity and effect of the flotation process.

The selection and combination of reagents are crucial in actual production and usually need to be customized and optimized according to the characteristics of the ore, the process flow and production requirements. Follow us to get more information on the types of reagents, their mechanisms of action, and their applications in mineral processing and metallurgy.

In order to continuously improve the quality of our products and services, we have established a mineral processing experimental research laboratory, which can provide customers with ore selectivity experiments and personalized pharmaceutical system development, helping customers achieve the best production technology indicators.

Our production base covers an area of more than 170,000 square meters, with a provincial technology center equipped with advanced equipment, demonstrating our firm commitment to maintaining strong technical strength. We follow modern enterprise standards and focus on intrinsic safety, resource conservation, environmental friendliness and technological innovation. The world-leading methanol ammoxidation process is used to produce Sodium Cyanide, which not only ensures high safety standards and meets environmental requirements, but also increases equipment output while minimizing production energy consumption.

Shaanxi Erlian Chemical Co., Ltd. adheres to the business philosophy of "integrity, perseverance, professionalism, mutual benefit, cooperation and win-win". With a wide network and a skilled team, we are able to provide customers with professional, personalized and tailor-made services. In many fields such as international trade, logistics, industry, technology, finance, etc., we have established close cooperative relationships.

Looking to the future, we will continue to strengthen China's trade ties with the global market and establish mutually beneficial partnerships with stakeholders from different backgrounds. Our vision is to continue to share the platform with friends from all walks of life at home and abroad and move towards success together.

- Random Content

- Hot content

- Hot review content

- T-610 collector Salicyl oxime acid derivative Content 3.5%

- Digital Electronic Detonator(Delay time 0~ 16000ms)

- Potassium Permanganate – Industrial Grade

- Gold Ore Dressing Agent Safe Gold Extracting Agent Replace Sodium Cyanide

- Pharmaceutical Grade Zinc Acetate

- Isobutyl vinyl ether 98% high purity certified Professional producer

- 99% Animal Feed Additive DL Methionine

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 3Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Oxalic acid for mining 99.6%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3Zinc chloride ZnCl2 for High Molecular Weight Polymers Initiator

- 4High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 5High Quality Sodium Ferrocyanide / Sodium Hexacyanoferr

- 6Gold Ore Dressing Agent Safe Gold Extracting Agent Replace Sodium Cyanide

- 7Sodium Cyanide 98%+ CAS 143-33-9

Online message consultation

Add comment: