DESCRIPTION

Digital Electronic Detonator: A high precision tool for complex mining operations and quarry blasting. The ability to program the blast delay with millisecond accuracy helps to effectively destroy the rock and reduce the possibility of earthquakes affecting nearby areas. Ideal for quarries, mines and construction projects.

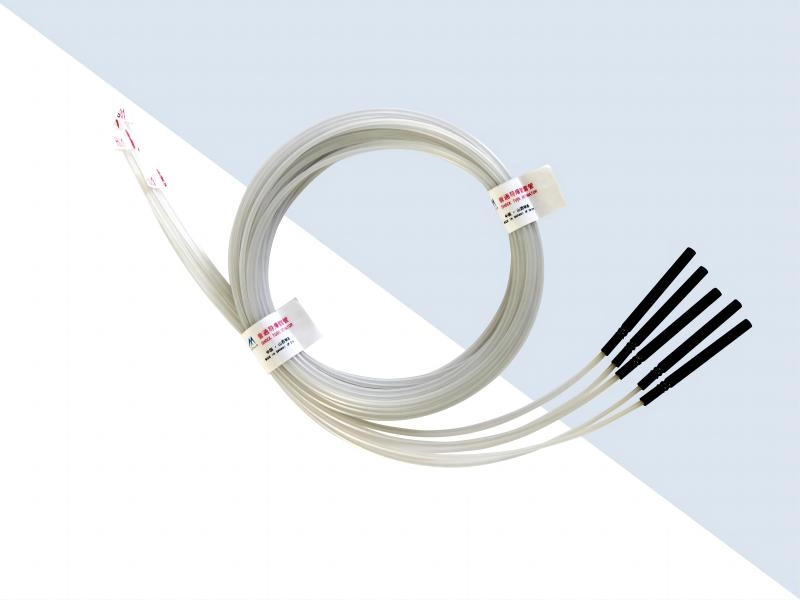

EDD Initiation system

Digital electronic detonator( EDD) consists of special blasting machine and digital electronic detonator( EDD) , which can meet all kinds of complex blasting designs.

Blasting machine is mainly used for the set and modification of EDD delay time. It also has network detection function and initiation function for both single detonator blasting network. One blasting machine will initiate 4 0 0 pcs detonator at most. It will initiate more than 10000pcs detonators if they are connected into network.

PERFORMANCE

| Item | Performance |

| Delay time set and minimum delay interval | 0~ 16000ms ; 1ms |

| Delay Accuracy | Delay time≤100ms,Variation range: ± 1ms Delay time >100ms,Variation range <0.2% |

| Water resistance | Under normal temperature, immerse the electronic detonator in water with a pressure of (0.3±0.002) MPa for 4hrs. After being taken out,initiation performance does not change |

| Anti- temperature | In 85℃ for 4 hrs, no explosion.After taking out, detonate normally. In -40℃ for 4 hrs, After taking out, detonate normally. |

| Anti- temperature and impact resistance | The electronic detonator in -40℃for 3hrs and then in 85℃for 3hrs ,the temperature conversion time is 20s-30s , and the electronic detonator should not explode after three cycles .Aftertaking it out , at room temperature for 1h , and the electronic detonator can detonate normally. |

| Tensile | The electronic detonator last for 1min under the static tension of 19 .6N , the wires and plugs connectors should not be damaged or moved visually , and the electronic detonator be able to detonate normally. |

| Anti static | Leg-wire to leg-wire , leg-wire to shell(25KV/500PF/500Ω ) ,discharge no ignition Leg-wire to leg-wire , leg-wire to shell(8KV/2000PF/0Ω ) , discharge no ignition |

| Anti-stray current | 100mA stray current is introduced into the bus, and the detonator and initiator communicate normally. Single detonator applied stray current of 250mA for 5min, without accidental detonation. |

| Resistance to RF | RF energy with a power of 10w into the electronic detonator , and the electronic detonator should not explode in two modes:leg-wire to leg-wire and leg-wire to shell . |

| Anti-impact | Under the condition that the weight is (2.0 ±0.002) kg and the height is (0.8±0.01) n, the electronic detonator should not explode when it hits the head fuse and the charging part of the primary explosive respectively. |

| Flexibility | Under 50N, 90 ° angle gravity, no fracture or damage to the shell |

| Anti- drop | No explosion under 5 m of free drop and led drop |

| Jolt test | 150mn high, 60Hz frequency, 10min vibration, no explosion and structural damage of detonator. |

| Network test | Test and verify in two-way communication, make sure no problem , and blast successfully |

| Network capacity | Single blasting machine connects no more than 400pcs detonators; When over 6000pcs, use the synchronized blasting machine |

- Random Content

- Hot content

- Hot review content

- Industry Grade Electron grade 98% Sulfuric Acid H2SO4 Sulphuric Acid Battery Acid Industrial Sulfuric Acid

- Flexible Customer and Supplier Relations Specialist (Location: Thailand)

- Industrial concentrated nitric acid 55%-68%

- IPETC 95%Metal sulfide mineral collector Z-200

- Expanded AN explosive

- Digital Electronic Detonator(Delay time 0~ 16000ms)

- United Chemical GDA Gold Dressing Agent HS: 3824999999 – Eco-Friendly Substitute for Sodium Cyanide

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Sodium Hydroxide,Caustic Soda Flakes,Caustic Soda Pearls 96%-99%

- 5Nutritional Supplements Food Addictive Sarcosine 99% min

- 6Sodium Cyanide Import Regulations & Compliance – Ensuring Safe and Compliant Importation in Peru

- 7United Chemical's Research Team Demonstrates Authority Through Data-Driven Insights

Comments

Add comment: