DESCRIPTION

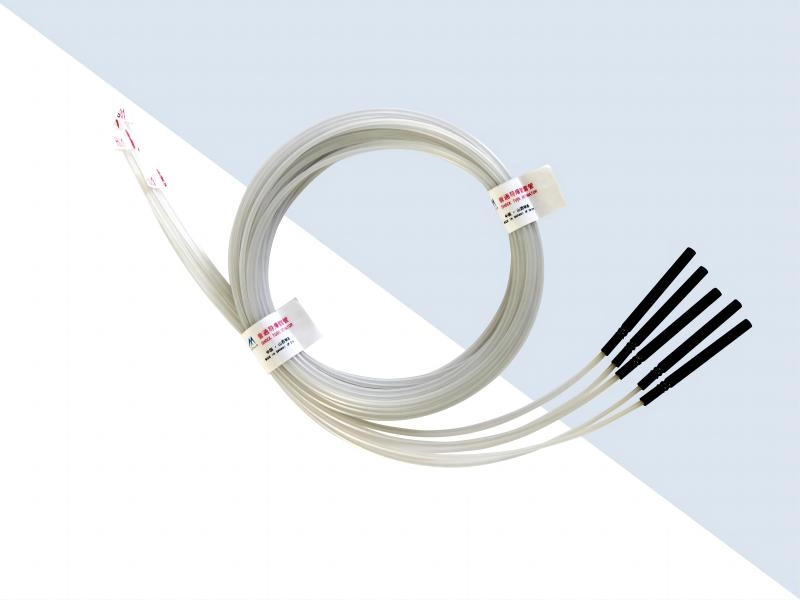

High-strength and high-precision detonator: suitable for underground and open-pit mining. High strength and resistance to physical impact make this product an ideal choice for explosion control in complex blasting applications such as mining, tunneling and infrastructure projects.

Performance

Item | Performance | |

Jolt test | No explosion, structural loose or damage after vibrating for 10mins in the vibration machine | |

Initiating power | Use detonator No.4 to fire through 3mm thick lead plate, or No.8 to fire through 5mm thick lead plate, and the diameter of the hole is bigger than the out-diameter of the shell | |

Oil resistance | Immersed in 0#diesel at 75℃ under 0.3Mpa for 24hrs, put out and initiate, no misfire or incomplete explosion | |

Tensile | Surface detonator | Pull with 19.6N static forces for 1min, shock tube can not be pulled out |

Pull with 78.4 N static forces for 1min, shock tube can not be pulled out | ||

Water resistance | Surface detonator | Immersed in 1m deep water for 8hrs, performance doesn’t change |

In-hole detonator | Immersed in 30m deep water for 20hrs, performance doesn’t change | |

Surface detonator delay time listed as below:

Segment | 1 | 2 | 3 | 4 | 5 |

Delaytime | 25ms | 42ms | 65ms | 100ms | 150ms |

Inhole deto. delay time listed as below:

Segments | Delay time (ms ) |

1 | 350 |

2 | 450 |

3 | 500 |

4 | 550 |

5 | 650 |

6 | 800 |

7 | 1000 |

- Random Content

- Hot content

- Hot review content

- Industrial grade sodium hexametaphosphate 68% SHMP

- Digital Electronic Detonator(Delay time 0~ 16000ms)

- Seismic Electric Detonator(Anti static,Water Resistance)

- Dodecylbenzenesulfonic acid

- Fertilizer magnesium sulfate/magnesium sulfate monohydrate

- Phosphoric Acid 85% (Food grade)

- 97% 2-Hydroxypropyl methacrylate

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 3Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Oxalic acid for mining 99.6%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3Zinc chloride ZnCl2 for High Molecular Weight Polymers Initiator

- 4High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 5High Quality Sodium Ferrocyanide / Sodium Hexacyanoferr

- 6Gold Ore Dressing Agent Safe Gold Extracting Agent Replace Sodium Cyanide

- 7Sodium Cyanide 98%+ CAS 143-33-9

Comments

Add comment: