Properties of Zinc chloride

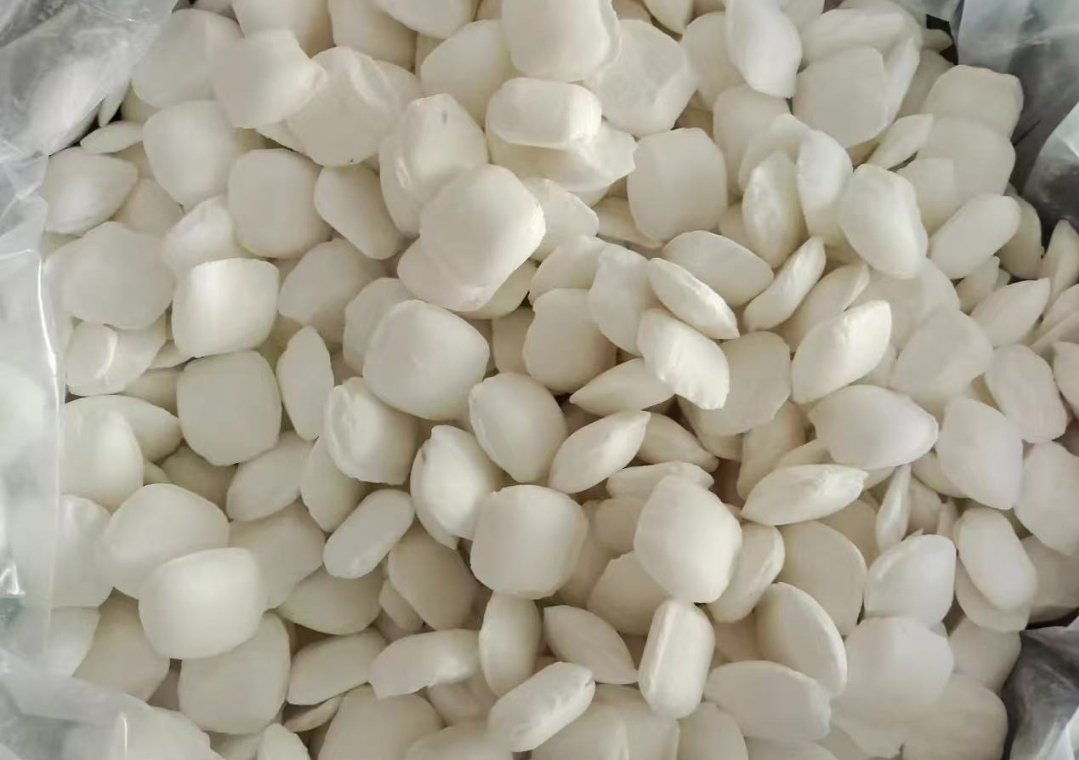

Zinc chloride (ZnCl₂) is a white or colorless crystal with high solubility. It can be completely dissolved in water, ethanol and glycerol. It is chemically stable, but hygroscopic. When exposed to air, it will gradually absorb water to form hydrates. Zinc chloride is highly corrosive, can dissolve a variety of metals and organic matter, and is toxic, so it needs to be handled with care.

Uses of zinc chloride

Zinc chloride has a wide range of applications in industry. In the field of metal processing, it is used as a flux for welding and brazing, which can effectively remove oxides on the metal surface and improve welding quality. In the chemical industry, zinc chloride is an important catalyst in organic synthesis reactions and is often used in the synthesis of dyes, spices and pharmaceutical intermediates. In addition, zinc chloride is also used as a wood preservative, rust remover and electrolyte in batteries. In the textile industry, it is used for fabric sizing and treatment to increase the strength and wear resistance of fibers.

Upstream and downstream raw materials of zinc chloride

The production of zinc chloride requires two main raw materials: zinc and hydrochloric acid. Zinc is the key raw material for zinc chloride production. It is usually extracted from ore and smelted to obtain pure zinc. Hydrochloric acid is another important raw material, which is produced by the reaction of hydrogen and chlorine. In the actual production process, zinc reacts with hydrochloric acid to produce zinc chloride and hydrogen. Downstream products include various zinc chloride products used in welding, brazing, catalysts and other fields. These products play an important role in different industrial fields.

Production process of zinc chloride

The production of zinc chloride is mainly carried out by direct synthesis, that is, the reaction of metallic zinc with hydrochloric acid to form a zinc chloride solution, and then solid zinc chloride is obtained through evaporation and crystallization. The reaction conditions need to be strictly controlled during the production process to ensure that the generated zinc chloride has high purity and stable quality. The by-product hydrogen produced during the production can be further utilized as an industrial gas to improve the economic benefits of production.

Storage method of zinc chloride

Zinc chloride is highly hygroscopic and corrosive, so special care should be taken when storing it. Zinc chloride should be stored in a dry, well-ventilated warehouse to avoid contact with moisture. Storage containers should be made of corrosion-resistant materials such as plastic or glass and be well sealed to prevent moisture from entering the air. Storage areas should be kept away from flammable and explosive items and chemicals such as strong acids and alkalis to prevent unexpected reactions.

Safe Handling of Zinc Chloride

Since zinc chloride is corrosive and toxic, appropriate protective measures must be taken when handling it. Operators should wear protective clothing, gloves and goggles to avoid direct contact of skin and eyes with zinc chloride. Once contact occurs, rinse immediately with plenty of water and seek medical attention as soon as possible. When handling zinc chloride waste, local environmental protection regulations should be followed and proper harmless treatment should be carried out to avoid pollution to the environment.

Zinc Chloride Market Analysis

The market demand for zinc chloride is mainly concentrated in the fields of welding, brazing, chemical catalysis and wood preservation. With the development of these industrial fields, the market demand for zinc chloride is also showing an upward trend. Especially in emerging market countries, the industrialization process is accelerating and the demand for zinc chloride is growing rapidly. The increasingly stringent environmental regulations have also promoted the demand for high-purity zinc chloride products. Overall, the zinc chloride market has broad prospects, but it also faces challenges such as fluctuations in raw material prices and rising production costs.

The future development trend of zinc chloride

In the future, the application areas of zinc chloride may be further expanded. For example, in the field of new energy batteries, zinc chloride is expected to be used as a new electrolyte material to improve the performance and life of batteries. With the development of green chemical industry, the application of zinc chloride in environmentally friendly catalysts and green chemical processes will also receive more attention. The production process of zinc chloride will develop in the direction of high efficiency, energy saving and environmental protection to meet market demand and environmental protection requirements.

in conclusion

As an important chemical raw material and intermediate, zinc chloride plays a variety of key roles in the industry. Its excellent chemical properties and wide range of applications make it an important player in the market. By optimizing the production process and strengthening safety management, the production efficiency and quality of zinc chloride can be effectively improved. In the future, with the continuous advancement of industrial technology and the improvement of environmental protection requirements, the application prospects of zinc chloride will be broader.

- Random Content

- Hot content

- Hot review content

- Lead nitrate 99%

- Flexible Customer and Supplier Relations Specialist (Location: India)

- IPETC 95%Metal sulfide mineral collector Z-200

- High-strength, High-precision Shock Tube Detonator

- Thiourea 99% high activity Professional Producer

- calcium chloride anhydrous for food

- Fertilizer magnesium sulfate/magnesium sulfate monohydrate

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Sodium Hydroxide,Caustic Soda Flakes,Caustic Soda Pearls 96%-99%

- 5Nutritional Supplements Food Addictive Sarcosine 99% min

- 6Sodium Cyanide Import Regulations & Compliance – Ensuring Safe and Compliant Importation in Peru

- 7United Chemical's Research Team Demonstrates Authority Through Data-Driven Insights

Online message consultation

Add comment: