Zinc chloride is a common chemical substance with many uses. It is widely used in chemical production, pharmaceutical preparations, electroplating processing and other fields. Zinc chloride can be dissolved in water, but some precautions need to be taken during the dissolution process to ensure safety and efficiency. The following are tips and precautions for dissolving Zinc chloride:

1. Use dry zinc chloride

Before dissolving zinc chloride, you need to make sure that the zinc chloride is dry. Wet zinc chloride will cause hydrogen to be produced during the dissolution process, increasing the danger of the operation. Therefore, in experiments or production, dry zinc chloride should be selected for dissolution operations.

2. Pay attention to the dissolution temperature

The dissolution temperature of zinc chloride is a key parameter. At room temperature, zinc chloride can be dissolved in water. However, if the dissolution temperature is too high, the reaction will be violent, generating a lot of heat and gas. Therefore, when dissolving zinc chloride, the dissolution temperature must be controlled to avoid accidents.

3. Control the stirring speed

When dissolving zinc chloride, the stirring speed is also a factor that needs attention. Stirring too fast will cause zinc chloride to dissolve too quickly in water, generating a lot of heat, thereby increasing the risk of operation. Therefore, it is necessary to control the stirring speed to ensure a smooth dissolution process.

4. Stay away from flammable items

When dissolving zinc chloride, you need to stay away from flammable items. Since zinc chloride produces hydrogen when it dissolves, once it comes into contact with flammable items, it will increase the risk of fire. Therefore, when dissolving zinc chloride, choose a safe place to operate.

Dissolving zinc chloride is a process that requires careful operation. It is necessary to ensure the safety of the operating environment, control the dissolving temperature and stirring speed, and stay away from flammable items. Only in this way can the chemical properties of zinc chloride be better utilized to achieve the desired effect.

- Random Content

- Hot content

- Hot review content

- Flexible Customer and Supplier Relations Specialist:Location: Laos

- Powdery emulsion explosive

- Thiourea 99% high activity Professional Producer

- Citric acid-Food Grade

- Cobalt Sulfate 98% Brown yellow or red crystal

- Sodium Dimethyldithiocarbamate 95% solid, 40% liquid

- Strontium carbonate

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Sodium Cyanide (CAS: 143-33-9) End user certificate (Chinese and English version)

- 7Anhydrous Oxalic acid 99.6% Industrial Grade

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 3Sodium Cyanide 98%+ CAS 143-33-9

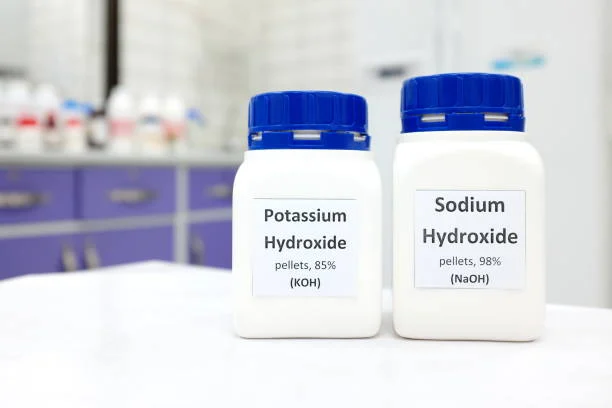

- 4Sodium Hydroxide,Caustic Soda Flakes,Caustic Soda Pearls 96%-99%

- 5Nutritional Supplements Food Addictive Sarcosine 99% min

- 6Sodium Cyanide Import Regulations & Compliance – Ensuring Safe and Compliant Importation in Peru

- 7United Chemical's Research Team Demonstrates Authority Through Data-Driven Insights

Online message consultation

Add comment: