I. Introduction

Cyanide sodium, a highly toxic chemical compound, demands strict adherence to safety protocols when handled. With its potential to cause severe harm and even endanger lives, understanding the correct procedures for handling Sodium Cyanide is of utmost importance. In this article, we will explore the various precautions and steps that should be taken to ensure the safe handling of this dangerous substance.

II. Understanding Sodium Cyanide

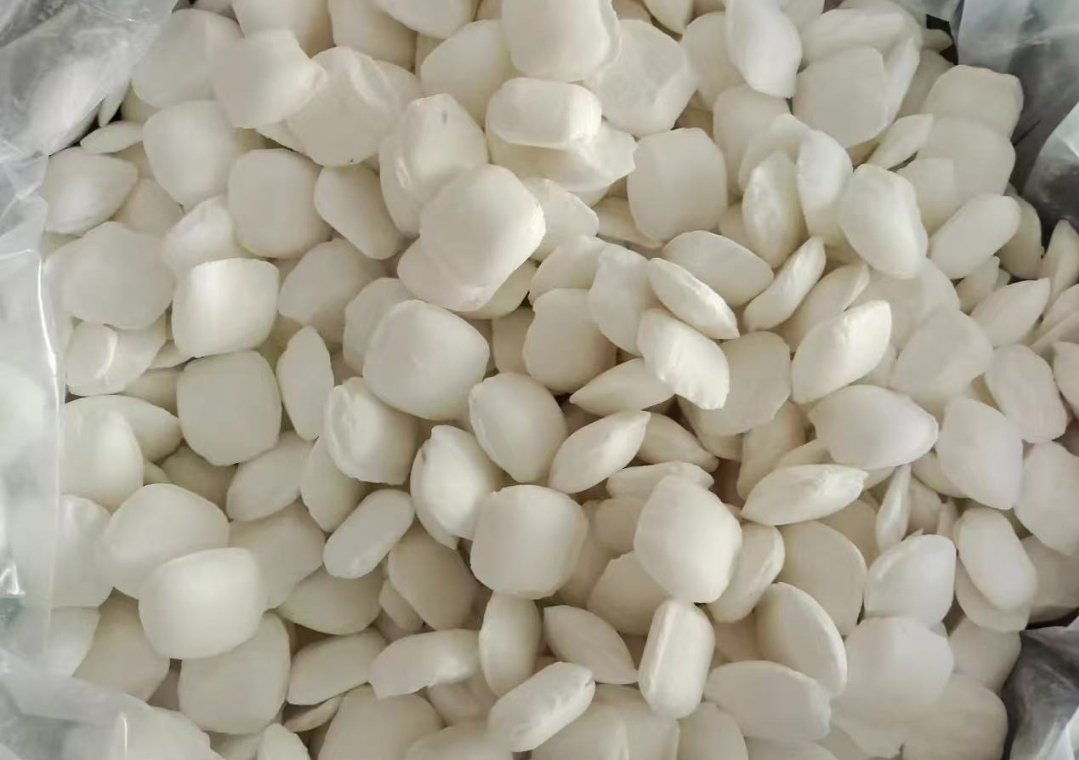

Sodium cyanide is an inorganic compound with the chemical formula NaCN. It typically appears as white crystalline granules or powder, which is prone to deliquescence. It has a faint, bitter almond odor. This compound is highly soluble in water, and its aqueous solution exhibits strong alkalinity. Sodium cyanide is a crucial basic chemical raw material, finding extensive applications in fields such as basic chemical synthesis, electroplating, metallurgy, and organic synthesis of pharmaceuticals and pesticides. It serves as a complexing agent and masking agent, playing an essential role in various industrial processes. However, due to its extreme Toxicity, it demands the highest level of caution and safety measures during handling.

III. Key Safety Precautions

III.1 Personal Protective Equipment (PPE)

When handling sodium cyanide, the correct selection and proper use of personal protective equipment are crucial. Firstly, a high-quality dust mask should be chosen. It is recommended to use masks that meet the standards of N95 or higher in countries like the United States, or FFP2 or above in Europe. These masks can effectively filter out fine particles of Sodium cyanide dust, preventing inhalation. When wearing the mask, ensure a snug fit around the nose and mouth, with no gaps to avoid any leakage.

Secondly, for hand protection, different types of gloves are available depending on the situation. When handling solid sodium cyanide, thick, chemical-resistant gloves made of materials like nitrile rubber are preferred. They offer good abrasion resistance and can block the penetration of the chemical. When dealing with sodium cyanide solutions, in addition to chemical resistance, gloves need to have better waterproof performance. It is advisable to choose gloves that are specifically designed for handling corrosive liquids. After using the gloves, they should be carefully removed to avoid contaminating other surfaces and washed thoroughly with running water.

Finally, chemical splash goggles are essential to protect the eyes. These goggles should have a wide field of vision and a good seal to prevent any splashes of sodium cyanide solution from entering the eyes. They should also be impact-resistant to avoid damage from accidental collisions. When wearing goggles, adjust the straps to ensure a comfortable and secure fit.

III.2 Avoiding Inhalation and Skin Contact

To prevent inhalation of sodium cyanide dust or gas, it is necessary to ensure good ventilation in the workplace. Install local exhaust ventilation systems near the handling area to quickly remove any airborne particles. When opening containers of sodium cyanide or performing operations that may generate dust, such as weighing or transferring, do so in a slow and careful manner to minimize dust dispersion. Workers should also avoid standing downwind of the operation to reduce the risk of inhalation.

Preventing skin contact is equally important. Always wear long-sleeved work clothes and trousers to cover the skin as much as possible. Avoid wearing clothing with holes or tears that could expose the skin. In case of accidental contact with sodium cyanide, immediately remove the contaminated clothing and wash the affected area thoroughly with running water for at least 15 minutes. If there are open wounds or abrasions on the skin, extra caution must be taken to prevent contact, as the chemical can enter the body more easily through these areas.

III.3 Eye Protection

In addition to wearing chemical splash goggles, it is necessary to have emergency eyewash stations readily available in the workplace. In the event that sodium cyanide does come into contact with the eyes, immediately rinse the eyes with copious amounts of clean, running water for at least 15 minutes. Do not rub the eyes, as this could cause further damage. Tilt the head slightly to the side to allow the water to flow over the entire eye surface. After rinsing, seek medical attention immediately. Even if there are no immediate symptoms, it is still advisable to have a professional examination to rule out any potential damage.

III.4 Spill Handling

In case of a sodium cyanide spill, it is essential to act quickly and calmly. First, immediately evacuate the area to ensure the safety of personnel. Only trained emergency response personnel wearing appropriate PPE should approach the spill site. Use a plastic or non-sparking shovel to carefully scoop up the spilled sodium cyanide and transfer it to a clean, sealed container. Avoid using metal tools that could react with the chemical. Absorbent materials such as vermiculite or dry sand can be used to soak up small amounts of spilled liquid, but they must be disposed of properly afterwards. Do not allow the spilled sodium cyanide to come into contact with water or other substances that could cause a chemical reaction. Once the spill has been contained, contact the relevant environmental and safety authorities for proper disposal guidance.

III.5 Chemical Compatibility

Sodium cyanide must be kept away from acids and weak bases at all times. When it comes into contact with acids, it can rapidly release highly toxic hydrogen cyanide gas, which poses a serious threat to life. Therefore, do not store acids or weak bases in the same area as sodium cyanide. When handling sodium cyanide, make sure that the work surface and any tools used are free from acidic or basic residues. If there is a risk of accidental contact, have emergency ventilation and gas detection equipment in place to quickly respond to any potential gas release.

III.6 Storage Conditions

The storage environment for sodium cyanide must meet strict requirements. Store it in a cool, dry, and well-ventilated area. The ideal temperature range is typically between 10°C and 25°C, as higher temperatures can accelerate the decomposition of the chemical. The relative humidity should be kept below 60% to prevent moisture absorption, which could lead to the formation of hydrogen cyanide gas. Use sealed containers made of materials that are resistant to sodium cyanide, such as high-density polyethylene or stainless steel. Label the containers clearly with the name, concentration, and hazard warnings of the chemical. Store the containers on shelves or racks at a proper height to prevent accidental damage. Regularly inspect the storage area and containers for any signs of leakage or damage.

IV. Emergency Response

IV.1 First Aid Measures

In case of accidental inhalation of sodium cyanide dust or gas, immediately move the victim to a well-ventilated area with fresh air. Loosen any tight clothing around the neck and chest to facilitate breathing. If the person has difficulty breathing or has stopped breathing, perform artificial respiration immediately. However, avoid mouth-to-mouth resuscitation and use a bag-valve-mask or other appropriate breathing apparatus if available. Call emergency medical services and continue artificial respiration until help arrives.

If sodium cyanide comes into contact with the skin, quickly remove any contaminated clothing. Wash the affected area thoroughly with large amounts of running water for at least 15 minutes. Use mild soap if necessary, but avoid scrubbing vigorously as it may damage the skin. After rinsing, cover the area with a clean, dry cloth and seek medical attention immediately.

In the event of eye contact, immediately flush the eyes with copious amounts of clean, running water for at least 15 minutes. Tilt the head to the side to ensure that the water reaches all parts of the eye. Do not rub the eyes as it can cause further damage. After rinsing, keep the eyes closed and seek medical help right away.

If sodium cyanide is ingested accidentally, do not induce vomiting unless instructed by medical professionals. Drink a large amount of water or milk immediately to dilute the chemical in the stomach. Call emergency medical services and provide them with as much information as possible about the ingestion, such as the amount and time of ingestion.

IV.2 Fire and Explosion Hazards

Although sodium cyanide itself is not flammable, it can release highly toxic hydrogen cyanide gas when heated to decomposition. In case of a fire involving sodium cyanide, firefighters must wear full protective gear, including self-contained breathing apparatuses (SCBA), chemical-resistant suits, gloves, and boots. Use dry chemical powder, carbon dioxide, or other appropriate extinguishing agents to suppress the fire. Avoid using water as it can react with sodium cyanide and release more toxic gases. Evacuate the surrounding area to a safe distance and prevent anyone from entering the smoke or gas plume. After the fire is extinguished, handle the remaining sodium cyanide and any contaminated materials with extreme caution to avoid secondary pollution.

V. Training and Awareness

Proper training for personnel handling sodium cyanide is non-negotiable. All operators must receive comprehensive training that includes in-depth knowledge of the chemical's properties, potential hazards, and the correct handling procedures. This training should cover not only the day-to-day operations but also emergency response scenarios.

Regular safety drills and simulations are essential to ensure that employees can respond quickly and effectively in case of an accident. These drills should mimic real-life situations such as spills, leaks, or accidental exposures. By participating in these exercises, employees become familiar with the emergency response protocols, including how to use safety equipment, evacuate the area, and administer first aid.

Furthermore, continuous education and refresher courses are necessary to keep employees updated on the latest safety regulations and best practices. As new research or incidents related to sodium cyanide handling emerge, it is crucial that operators are informed and adapt their procedures accordingly. This ongoing learning process helps maintain a high level of safety awareness and competence in the workplace.

VI. Conclusion

In conclusion, handling sodium cyanide demands the highest level of caution and strict adherence to safety protocols. The potential consequences of mishandling this toxic compound are severe, not only for the individuals directly involved but also for the surrounding environment. By understanding and implementing the necessary safety measures, we can minimize the risks associated with sodium cyanide handling. Continuous training and awareness are essential to ensure that all personnel stay updated on the latest safety practices. Remember, safety is a shared responsibility, and every precaution taken today can prevent a potential disaster tomorrow.

- Random Content

- Hot content

- Hot review content

- Flexible Customer and Supplier Relations Specialist (Location: Nigeria)

- industry Electric Detonator

- Sodiumsulfite Technical Grade 96%-98%

- Thiourea 99% high activity Professional Producer

- Pine oil 85% High Quality Pinitol oil 85% Light Yellow To Colorless Oily Liquid

- Fertilizer magnesium sulfate/magnesium sulfate monohydrate

- United Chemical GDA Gold Dressing Agent HS: 3824999999 – Eco-Friendly Substitute for Sodium Cyanide

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5Sodium Cyanide (CAS: 143-33-9) End user certificate (Chinese and English version)

- 6China factory Sulfuric Acid 98%

- 7Anhydrous Oxalic acid 99.6% Industrial Grade

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Sodium Hydroxide,Caustic Soda Flakes,Caustic Soda Pearls 96%-99%

- 5Nutritional Supplements Food Addictive Sarcosine 99% min

- 6Sodium Cyanide Import Regulations & Compliance – Ensuring Safe and Compliant Importation in Peru

- 7United Chemical's Research Team Demonstrates Authority Through Data-Driven Insights

Online message consultation

Add comment: