Safety storage and transportation specifications of Sodium Hydrosulfide in the field of chemical production raw materials

Abstract

Sodium hydrosulfide, as a common chemical production raw material, possesses strong alkalinity and reducing properties, necessitating strict adherence to safety regulations during storage and transportation. This article will provide a detailed overview of the physical and chemical properties of sodium hydrosulfide, an assessment of its hazards, first aid measures, fire-fighting measures, emergency response to leaks, operational handling and storage, exposure control/personal protection, physicochemical characteristics, stability and reactivity, toxicological data, ecological data, waste disposal, transportation information, and regulatory information, in order to ensure its safety and reliability.

I. Physical and Chemical Properties

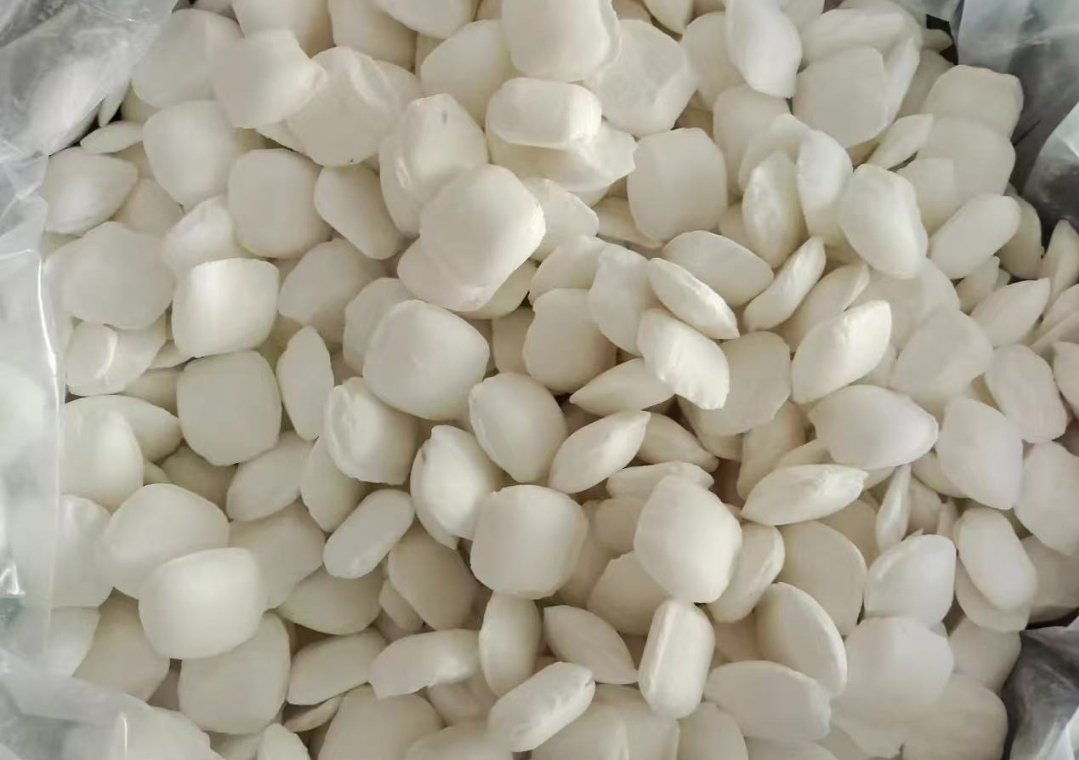

Sodium hydrosulfide is a white crystalline powder with strong alkalinity and reducing properties. Its molecular formula is NaHS, and its molecular weight is 56.06. The melting point is 100°C, and the boiling point is 140°C. Sodium hydrosulfide is easily soluble in water, producing sodium hydroxide and hydrogen sulfide.

II. Overview of Hazards

Sodium hydrosulfide is highly irritating to the eyes, skin, and mucous membranes. Inhalation of its vapors can cause respiratory irritation symptoms. Ingestion can lead to gastrointestinal burns, mucosal erosion, bleeding, and shock. Additionally, sodium hydrosulfide reacts with acids to release flammable hydrogen sulfide gas and reacts violently with oxidizers and acidic substances.

III. First Aid Measures

In case of skin contact, immediately remove contaminated clothing and rinse the affected area with plenty of flowing water for at least 15 minutes. For eye contact, immediately lift the eyelids and rinse thoroughly with plenty of flowing water or saline for at least 15 minutes. If inhaled, move the patient to fresh air and ensure the airway is clear. In case of ingestion, rinse the mouth, administer milk or egg whites, and seek medical attention immediately.

IV. Fire-Fighting Measures

Sodium hydrosulfide should be stored in a cool, well-ventilated dedicated warehouse, away from sources of ignition and heat. It should be stored separately from oxidizers and acids, and mixing is strictly prohibited. Equip the storage area with appropriate types and quantities of fire-fighting equipment and leak emergency response devices. The storage area should have suitable materials to contain any leaks.

V. Emergency Response to Leaks

Isolate the contaminated leak area and restrict access. Emergency responders are advised to wear dust masks (full face) and acid-alkali protective clothing. Contact with broken containers and leaked materials is prohibited until appropriate protective clothing is worn. Cut off the leak source if possible. For small leaks: avoid dust generation and use a clean shovel to collect the material in a dry, clean, covered container. For large leaks: cover with plastic sheeting or canvas. Then collect and recycle or transport to a waste disposal site for treatment.

VI. Operational Handling and Storage

Operational Precautions: Conduct operations in a closed environment and provide adequate local exhaust ventilation. Prevent dust from being released into the workshop air. Operators must undergo specialized training and strictly adhere to operating procedures. It is recommended that operators wear dust masks (full face), rubber acid-alkali resistant clothing, and rubber acid-alkali resistant gloves. Keep away from sources of ignition and heat; smoking is prohibited in the workplace. Use explosion-proof ventilation systems and equipment. Avoid dust generation and contact with oxidizers and acids. Special care should be taken to avoid contact with water. Equip the area with appropriate types and quantities of fire-fighting equipment and leak emergency response devices. Empty containers may retain harmful residues.

Storage Precautions: Store in a cool, well-ventilated dedicated warehouse, away from sources of ignition and heat. Prevent direct sunlight exposure. Store separately from oxidizers and acids, and mixing is strictly prohibited. Equip the storage area with appropriate types and quantities of fire-fighting equipment. The storage area should have suitable materials to contain any leaks.

VII. Exposure Control / Personal Protection

Occupational exposure limit: China MAC (mg/m3): No standard has been established. Former Soviet Union MAC (mg/m3): No standard has been established. TLVTN: No standard has been established. TLVWN: No standard has been established. Monitoring method: Engineering control: Closed operation, provide sufficient local exhaust. Respiratory system protection: When the concentration in the air exceeds the standard, a self-priming filter dust mask must be worn. When rescuing or evacuating in an emergency, an air respirator should be worn. Eye protection: Wear chemical safety glasses. Body protection: Wear rubber acid and alkali resistant clothing. Hand protection: Wear rubber acid and alkali resistant gloves. Other protection: Smoking, eating and drinking are prohibited in the workplace, and wash hands before meals. After work, take a shower and change clothes. Maintain good hygiene habits.

VIII. Physicochemical Properties

Appearance and properties: White to colorless crystalline powder or flaky crystals with the smell of hydrogen sulfide. Melting point (℃): greater than 100 Relative density (water = 1): 1.79 Solubility: soluble in water, soluble in methanol and other organic solvents. Main use: used as analytical reagents, etc. Incompatible materials: strong oxidants, strong acids. Conditions to avoid contact: humid air. Polymerization hazard: no polymerization Decomposition products: hydrogen sulfide, sulfur oxides.

IX. Stability and Reactivity

Stability: Stable Polymerization hazard: No polymerization Conditions to avoid: Heat Incompatible materials: Strong acid, strong oxidizer Hazardous decomposition products: Hydrogen sulfide Combustion (decomposition) products: Hydrogen sulfide, sulfur oxide Toxicity classification Poisoning Acute toxicity Oral-rat LD50: 560 mg/kg Irritation data Eyes-rabbit 500 mg/24 hours Severe irritation Skin-rabbit 500 mg/24 hours Severe irritation Inhalation-rat TCLo: 1400ppm/4 hours Hazardous characteristics Reacts with acid to release flammable hydrogen sulfide gas. It can react violently with oxidants to cause combustion or explosion.

- Random Content

- Hot content

- Hot review content

- Powdery emulsion explosive

- calcium chloride anhydrous for food

- Hydrogen Peroxide

- Phosphoric Acid 85% (Food grade)

- Sodium sulphate 99% Pharmacy Grade

- Lithium chloride, 99.0%,99.5%

- Cupric Chloride 98%

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Sodium Hydroxide,Caustic Soda Flakes,Caustic Soda Pearls 96%-99%

- 5Nutritional Supplements Food Addictive Sarcosine 99% min

- 6Sodium Cyanide Import Regulations & Compliance – Ensuring Safe and Compliant Importation in Peru

- 7United Chemical's Research Team Demonstrates Authority Through Data-Driven Insights

Online message consultation

Add comment: