Background

In the past two decades, with the rapid development of science and technology and economic construction, the demand for mineral resources has been increasing day by day. The availability of easily mined and selected single rich ores is becoming increasingly rare. The mining of complex ores with fine embedded particle sizes and low grades is on the rise, and there are growing demands for product variety and quality. To meet the needs of various sectors of the national economy for mineral products, there is an urgent requirement to develop new mineral processing methods that are efficient, economically beneficial, and conducive to environmental management.

The method of recovering valuable metals from acidic water using Sodium hydrosulfide has a high recovery rate and significant economic benefits. The process includes the following steps:

01.High-Level Water Storage Tank

The acidic water generated during the mining process first flows from the high-level water storage tank into the first iron removal reaction tank, where lime is added. The trivalent iron ions in the acidic water precipitate along with calcium sulfate, and most of the trivalent iron ions are removed from the acidic water.

02.First Iron Removal Reaction Tank

The reaction liquid flows from the iron removal reaction tank into the first degassing tank, where a flocculant is added.

03.Second Iron Removal Reaction Tank

The raw water, which has been thoroughly mixed with lime slurry and flocculant, flows into the iron removal thickening tank, where the iron hydroxide and calcium sulfate precipitate settle to the bottom of the thickening tank.

04.First Degassing Tank

The acidic water containing valuable metal ions, from which a large amount of trivalent iron ions has been removed, flows by gravity into the metal sulfide reactor.

05.Metal Sulfide Reactor

In the metal sulfide reactor, the acidic water is thoroughly mixed with metal sulfide precipitate and sodium hydrosulfide, generating metal sulfide particles.

06.Second Degassing Tank

The mixed liquid containing metal sulfide concentrate flows by gravity into the second degassing tank attached to the metal sulfide reactor, where a flocculant is added to promote the agglomeration of metal sulfide particles into larger particles.

07.Metal Sulfide Thickening Tank

The concentrated metal sulfide precipitate settles to the bottom of the metal sulfide thickening tank. A scraper removes the settled precipitate to the center of the bottom of the thickening tank. A reflux pump continuously recycles a portion of the precipitate from the bottom of the thickening tank back to the iron removal reaction tank, while the remaining precipitate is sent to the waste rock pile by a conveying pump.

08.Metal Sulfide Thickening Tank

The circulation pump continuously recycles a portion of the precipitate from the bottom of the metal sulfide thickening tank back to the metal sulfide reactor. The other portion of the bottom precipitate is sent to a plate-and-frame filter press to be concentrated into metal sulfide concentrate.

The advantages of the method for recovering valuable metals from acidic water using sodium hydrosulfide are as follows:

Directly recovering valuable metals from acidic wastewater generated by mines costs about half of traditional mineral processing methods. The grade of the recovered valuable metal sulfides is nearly twice that of traditional mineral processing methods, with a high recovery rate and significant economic benefits. The wastewater after recovery contains fewer heavy metal ions, resulting in lower wastewater treatment costs and good environmental benefits

- Random Content

- Hot content

- Hot review content

- Unlocking the Power of Mineral Processing Chemicals: Enhancing Efficiency and Sustainability

- Oxalic acid for mining 99.6%

- Sodium Metal, ≥99.7%

- Ferrous Sulfate Industrial Grade 90%

- Potassium borohydride

- Sodium selenite,anhydrous 98%

- Fuel Additive Octane Value Booster Ferrocene

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 3Sodium Cyanide 98%+ CAS 143-33-9

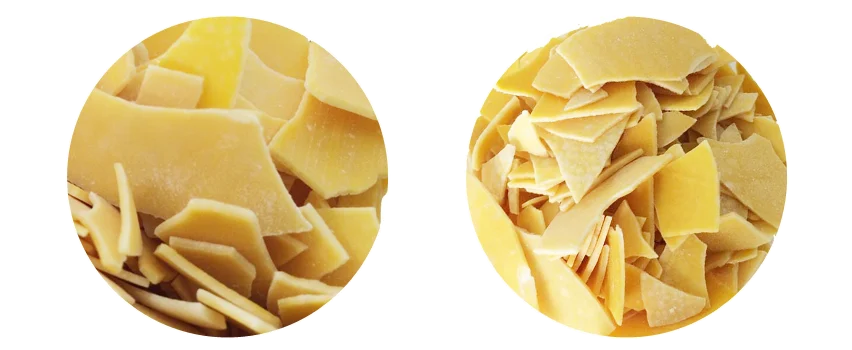

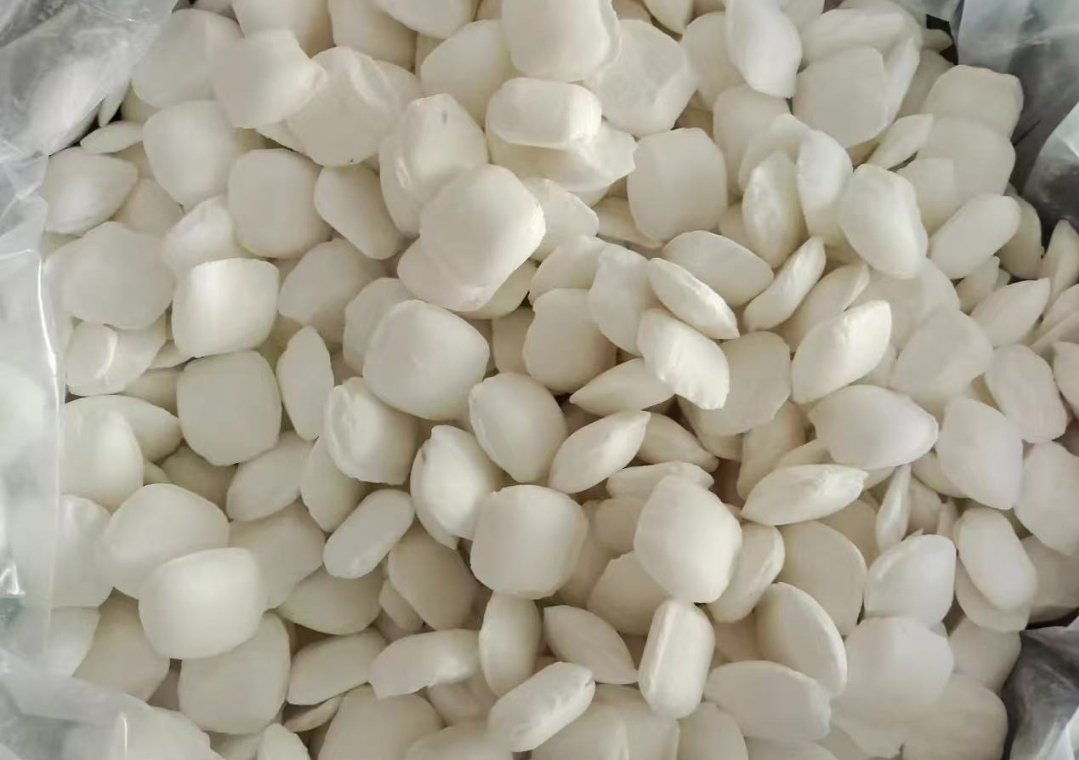

- 4Sodium Hydroxide,Caustic Soda Flakes,Caustic Soda Pearls 96%-99%

- 5Nutritional Supplements Food Addictive Sarcosine 99% min

- 6Sodium Cyanide Import Regulations & Compliance – Ensuring Safe and Compliant Importation in Peru

- 7United Chemical's Research Team Demonstrates Authority Through Data-Driven Insights

Online message consultation

Add comment: