Chemical Companies: Types and Focus on Chemical Users

There are many types of companies related to chemicals, mainly production companies, transportation companies, user companies, and waste disposal companies. Due to space limitations, this article will focus on chemical user companies, particularly manufacturing plants.

Chemicals in Manufacturing Plants

It’s well known that chemicals play a crucial role in the manufacturing process. In our previous discussions, we talked about some issues related to chemical management. Today, let’s discuss another important topic in chemical management: Chemical Inventory Lists.

Understanding the Chemicals Used and Stored in a Factory

To establish an effective chemical management system, the first essential step is to understand the chemicals used and stored in the factory. But how can you quickly and systematically understand these chemicals? It’s like understanding the staff of a factory or knowing the population of a town—you need a "roster" or "registry." Similarly, for chemical management, you can't do without a Chemical Inventory List.

01 - The Importance of a Chemical Inventory List

The significance of a Chemical inventory list is profound and far-reaching. In short, it helps the factory identify all the chemicals in use and their properties, ensuring that the factory complies with regulations and customer requirements. It also ensures the implementation of proper control measures to protect workers and the environment, ensuring compliance with chemical usage from the first layer of management.

A chemical inventory list helps the factory keep track of its chemical stocks, assisting in procurement decisions, increasing transparency and traceability, and promoting responsible chemical usage. Through effective chemical inventory management, companies can optimize their inventory structure, reduce unnecessary or expired stock, and lower inventory costs.

Although chemical inventory lists are vital, in practice, many factories don’t fully understand or utilize them. Some management teams take a minimal approach, thinking “as long as there’s a list, it’s good enough.” During factory audits, we often encounter incomplete chemical inventory lists, sometimes listing only chemical names (often names created by the factory itself), which barely meet the definition of a "list."

02 - Common Issues with Chemical Inventory Lists

Based on authoritative statistics and audit experience, it’s clear that "Chemical Inventory Lists" are one of the top ten problems in chemical management. Some common issues include:

A) Lack of a Chemical Inventory List

Many factories without a chemical inventory list simply aren’t aware of the requirement or don’t understand its importance. This reflects a broader issue with chemical management within the factory. In some cases, factories are aware of the requirement but struggle with creating the list due to a lack of understanding of the process or requirements, leading to delays or failures in establishing a list.

B) Incomplete Chemical Inventory Lists

Incompleteness can manifest in various ways, such as not including all chemicals used in the factory. This often happens with less commonly used chemicals, such as lubricants for equipment maintenance, cleaning agents, wastewater treatment chemicals, or newly purchased chemicals. Additionally, critical information may be missing, such as SDS (Safety Data Sheet) information, CAS numbers, hazard categories, or MRSL/RSL compliance. More often than not, these problems occur together.

C) Inaccurate Information in the Chemical Inventory List

Another common issue is inaccurate information in the list, often due to input errors or failure to update the list in a timely manner. For instance, an MSDS may have been updated, but the list wasn’t updated to reflect this change. Similarly, changes in the quantity of chemicals in storage, or expired chemicals, are not reflected in the list, leading to discrepancies.

03 - Solutions for Managing a Chemical Inventory List

To effectively and safely manage chemicals, a well-maintained chemical inventory list is essential. How can you create a comprehensive chemical inventory list? Here are a few key points:

First:

Factories should establish a robust chemical management procedure, outlining how to create and update the chemical inventory list, and specifying the content and format of the list.

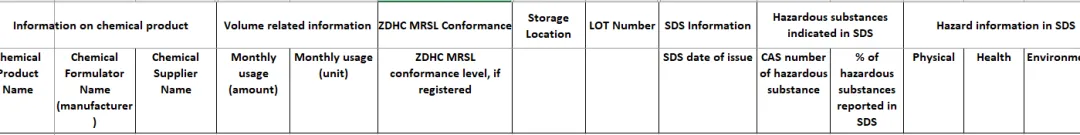

What should a typical list include? Two of the most common standards for chemical inventory management are ZDHC and Higg FEM.

ZDHC Requirements

The ZDHC chemical management system specifies that the Chemical Inventory List (CIL) must include the following:

Chemical name

SDS location

CAS number

Hazard information

ZDHC MRSL compliance

Stock quantity, delivery quantity, or usage quantity

Storage location

Higg FEM Requirements

The Higg FEM standard requires an even more comprehensive set of information for chemical inventory lists, including but not limited to:

Chemical name and type

Supplier/seller name and type

Manufacturer/formulator name

SDS in line with the Global Harmonized System (GHS)

Function

Hazard classification

Location/area of use

Storage conditions and location

Quantity of chemical used

CAS number

Batch number (if applicable)

MRSL compliance

Purchase date

Expiry date (if applicable)

Much of this information can be found in the SDS, such as chemical name, type, hazard classification, storage conditions, and CAS number. Information such as usage quantities, batch numbers, purchase dates, and expiry dates can be obtained from procurement records, chemical labels, etc. Factories can also include other valuable information as needed.

Second:

Factories should designate a qualified individual to maintain and manage the chemical inventory list, ensuring timely updates after procurement, storage, or use.

The designated person should have basic chemical knowledge and management skills, whether full-time or part-time. This expertise can be gained through education or continuous training.

How often should the chemical inventory list be updated? The ZDHC suggests that different types of information should be tracked at different frequencies. For instance, inventory checks should be conducted annually, while delivery and usage information should be updated monthly. For factories with higher usage volumes or varieties, more frequent updates (e.g., weekly or daily) may be implemented.

In the Higg FEM, the inventory list is required to be "current and accurate," implying real-time updates.

Lastly:

The chemical inventory list should cover all chemicals stored or used during the factory’s production processes, including those for operation and maintenance.

This includes all chemicals used in the manufacturing process, maintenance chemicals for tools/equipment, and chemicals used in wastewater treatment plants, cleaning agents, adhesives, paints, dyes, pigments, additives, etc.

Do you now have a clearer understanding of the "chemical list" and feel it is much simpler?

If you have any questions, you can leave a message at the bottom of this article or contact us.

- Random Content

- Hot content

- Hot review content

- Polyethylene Glycol PEG - 2000/4000/6000/8000 alcohol ethoxylate surfactant

- Unlocking the Power of Mineral Processing Chemicals: Enhancing Efficiency and Sustainability

- Di(ethylene Glycol) Vinyl Ether

- Calcium Chloride 74% Flakes

- Caprylic/capric triglyceride

- Zinc sulfate monohydrate 98% Industrial & Feed Grade

- Ethylene carbonate

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Sodium Hydroxide,Caustic Soda Flakes,Caustic Soda Pearls 96%-99%

- 5Nutritional Supplements Food Addictive Sarcosine 99% min

- 6Sodium Cyanide Import Regulations & Compliance – Ensuring Safe and Compliant Importation in Peru

- 7United Chemical's Research Team Demonstrates Authority Through Data-Driven Insights

Online message consultation

Add comment: