Properties of Sodium Hydrosulfide

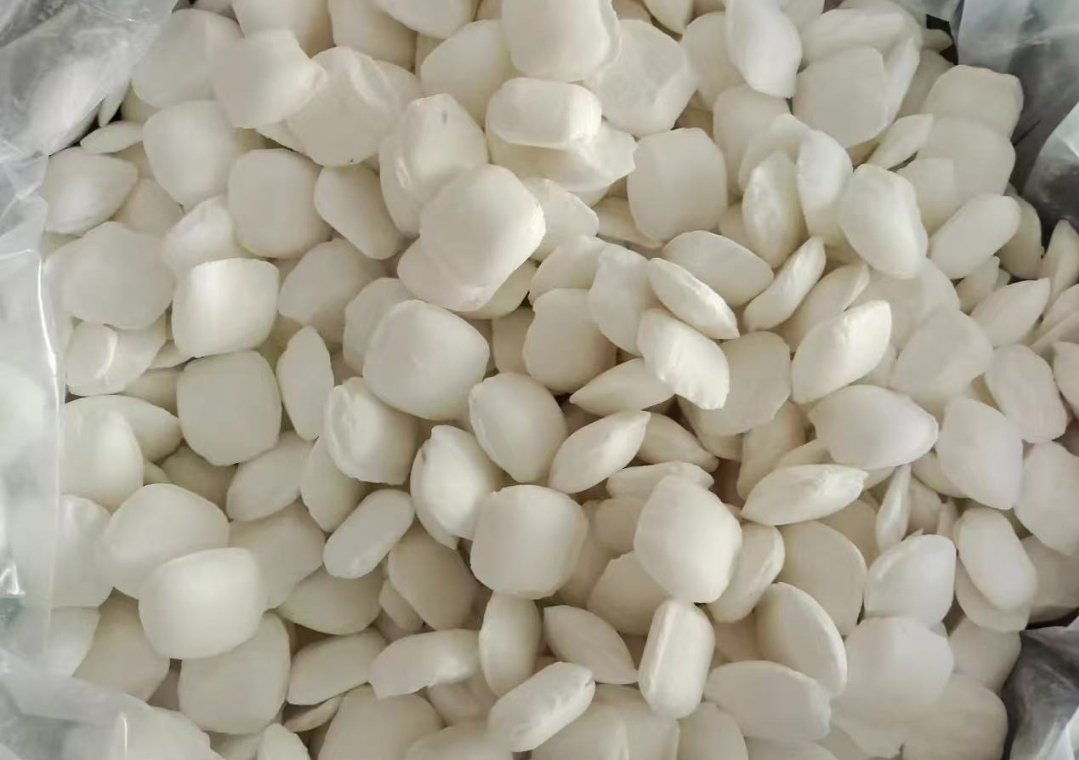

Sodium hydrosulfide (NaHS) is an inorganic compound with significant industrial applications. It typically exists in the form of colorless or light yellow crystals and has strong corrosive properties along with a pungent odor. Sodium hydrosulfide is highly soluble in water, releasing heat upon dissolution and forming an alkaline solution, with solubility increasing as the temperature rises. Chemically, sodium hydrosulfide dissociates in water to produce hydrosulfide ions (HS-), and it acts as a strong reducing agent, readily oxidizing to form sodium sulfide (Na2S).

Uses of Sodium Hydrosulfide

Sodium hydrosulfide has a wide range of applications across various industries. In mining, it is commonly used as a flotation agent, particularly in the beneficiation of non-ferrous metal ores, to separate metals such as copper, zinc, and nickel. In the leather industry, Sodium hydrosulfide serves as a dehairing agent and a desulfurizing agent, effectively removing sulfides from leather. It is also utilized in chemical manufacturing as a raw material for producing organic sulfides, dyes, and pharmaceuticals. In the paper industry, it is employed as a bleaching agent and deinking agent, significantly improving paper quality. Additionally, sodium hydrosulfide has applications in environmental protection, such as in wastewater treatment as a heavy metal chelating agent, helping to remove harmful metal ions from water.

Upstream and Downstream Raw Materials of Sodium Hydrosulfide

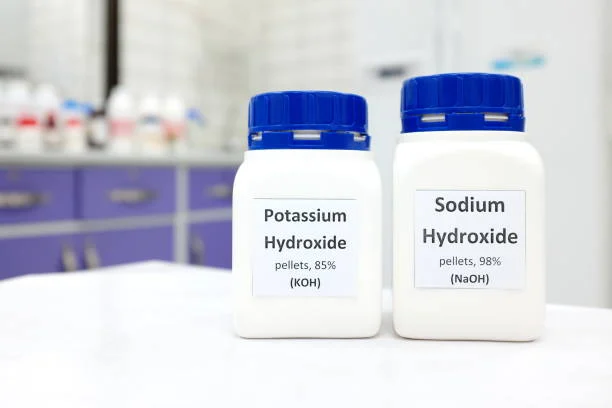

The main raw materials for the production of sodium hydrosulfide (NaHS) are hydrogen sulfide (H2S) and sodium hydroxide (NaOH). Hydrogen sulfide can be obtained from the processing of natural gas, petroleum, or coal, or it can be produced by the thermal decomposition of sulfur-containing minerals. Sodium hydroxide is typically produced by the electrolysis of brine (NaCl solution). The production process of sodium hydrosulfide generally involves the reaction of hydrogen sulfide gas with sodium hydroxide solution to produce:

\[ \text{H}_2\text{S} + \text{NaOH} \rightarrow \text{NaHS} + \text{H}_2\text{O} \]

This reaction is simple and efficient. The downstream products of sodium hydrosulfide production include flotation agents for mineral processing, dehairing agents for the leather industry, intermediates for chemical synthesis, bleaching agents for the paper industry, and heavy metal chelating agents for environmental protection.

Storage Methods for Sodium Hydrosulfide

Due to the strong corrosive properties and pungent odor of sodium hydrosulfide, special care is required during storage. It should be stored in a dry, well-ventilated warehouse to avoid moisture and exposure to air, as it is hygroscopic and can decompose. The storage environment temperature should be kept low to prevent decomposition due to high temperatures. Sodium hydrosulfide should be kept in sealed containers, typically using plastic drums or bags, and should not come into contact with acidic substances, as it reacts with acids to release toxic hydrogen sulfide gas. The warehouse should be equipped with good ventilation and emergency leak handling equipment to prevent accidents. Personnel handling and using sodium hydrosulfide should wear protective gear, such as gloves, safety goggles, and protective clothing, to minimize direct contact with the substance.

Market Status and Development Trends

The demand for sodium hydrosulfide is continuously growing, particularly driven by the mining and leather industries. The development of global mineral resources and the increasing demand for leather products have boosted the market demand for sodium hydrosulfide. With the tightening of environmental protection regulations, the application of sodium hydrosulfide in wastewater treatment is also gradually increasing. In the future, the market outlook for sodium hydrosulfide is optimistic, especially in the Asia-Pacific region, where the rapid industrialization in India and China will further drive the growth in demand for sodium hydrosulfide.

Safety and Environmental Protection

Safety and environmental protection issues must be given high priority during the production and use of sodium hydrosulfide. Due to its toxicity and corrosiveness, strict control over the production process is necessary to prevent leaks and pollution. Workplaces should be equipped with adequate ventilation systems and personal protective equipment. The treatment of wastewater and exhaust gases should also comply with environmental protection requirements to avoid harming the environment. Particularly when dealing with wastewater containing heavy metals, sodium hydrosulfide can effectively capture heavy metal ions, but the treated waste residue must be properly managed to prevent secondary pollution.

Conclusion

As an important chemical raw material, sodium hydrosulfide has a wide range of applications and a promising market outlook. Its properties determine its significant role in various industrial sectors. Due to its corrosiveness and toxicity, strict adherence to safety and environmental protection regulations is essential during the production, storage, and use of sodium hydrosulfide. In the future, with the advancement of industrialization and the enhancement of environmental awareness, the demand for sodium hydrosulfide will further increase, while also facing more stringent regulatory and technical requirements.

- Random Content

- Hot content

- Hot review content

- Oxalic acid for mining 99.6%

- Expanded AN explosive

- Potassium Permanganate – Industrial Grade

- Food Grade Ammonium Sulphate

- Maleic Anhydride - MA

- Lithium hydroxide 99% Solid

- Adipic acid 99% used as the material of nylon 66

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 3Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Oxalic acid for mining 99.6%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3Zinc chloride ZnCl2 for High Molecular Weight Polymers Initiator

- 4High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 5High Quality Sodium Ferrocyanide / Sodium Hexacyanoferr

- 6Gold Ore Dressing Agent Safe Gold Extracting Agent Replace Sodium Cyanide

- 7Sodium Cyanide 98%+ CAS 143-33-9

Online message consultation

Add comment: