Sodium Cyanide is a highly toxic chemical, and its Storage must adhere to strict safety requirements to prevent accidents. This article elaborates on these crucial safety aspects.

Storage Location

The storage location of Sodium cyanide must meet the following criteria:

Distance from Flammable and Explosive Substances: It should be kept far away from combustible and explosive materials to avoid the risks of fire or explosion.

Dry and Well - Ventilated Environment: The storage area needs to be dry and well - ventilated, and must be isolated from heat sources and ignition sources.

Regular Cleaning: Regular cleaning of the storage location is essential to ensure that Sodium Cyanide does not come into contact with impurities or dirt.

Proper Identification: The storage location should be clearly marked for easy management.

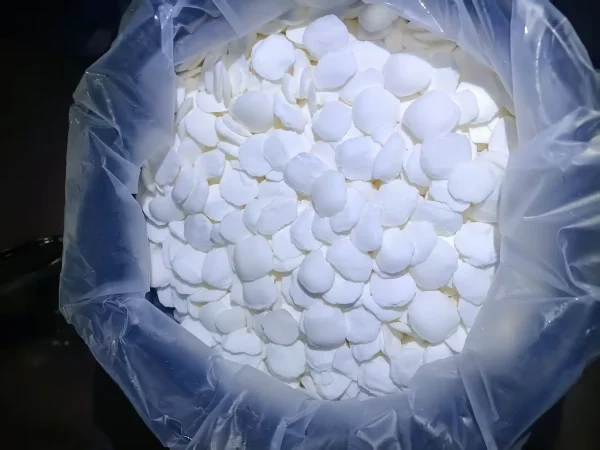

Storage Containers

Storage containers for sodium cyanide must satisfy the following requirements:

Specialized and Clearly - Labeled Containers: Only specialized containers should be used, and they must be clearly labeled.

Separate Storage: They must be stored separately from other items to prevent confusion.

Collision and Drop Prevention: Precautions should be taken to prevent collisions and drops to avoid liquid leakage and container breakage.

Preventive Measures

During the storage and use of sodium cyanide, the following measures must be implemented to prevent accidents:

Wearing Protective Equipment: All personnel handling sodium cyanide must wear personal protective equipment such as protective gloves and goggles.

Avoiding Direct Contact: Direct contact with sodium cyanide or inhalation of its vapors should be minimized during operation. Also, prevent it from coming into contact with the outside of the container.

Avoiding Water Contact: Sodium cyanide reacts violently with water, releasing toxic hydrogen cyanide gas. Therefore, it is crucial to avoid any contact with water.

Emergency Response: In case of an accident, appropriate emergency measures should be taken immediately, including promptly washing the contaminated areas to minimize the spread of contamination.

Conclusion

Sodium cyanide is a toxic chemical, and strict safety requirements must be followed during its storage and use to prevent accidents. For those who use sodium cyanide, a deep understanding of its properties and mastery of correct operating methods are essential to ensure personal safety and the safety of the surrounding environment.

- Random Content

- Hot content

- Hot review content

- Sodium Isopropyl Xanthate 90% SIPX

- High-strength, High-precision Shock Tube Detonator

- Barium carbonate 99% powder

- Triethanolamine(TEA)

- Calcium Chloride 74% Flakes

- 99% Animal Feed Additive DL Methionine

- Magnesium Sulfate

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 3Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Oxalic acid for mining 99.6%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3Zinc chloride ZnCl2 for High Molecular Weight Polymers Initiator

- 4High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 5High Quality Sodium Ferrocyanide / Sodium Hexacyanoferr

- 6Gold Ore Dressing Agent Safe Gold Extracting Agent Replace Sodium Cyanide

- 7Sodium Cyanide 98%+ CAS 143-33-9

Online message consultation

Add comment: