Sodium hydrosulfide (NaHS) is an important inorganic chemical widely used in various fields such as chemical industry, metallurgy, pharmaceuticals, pesticides, organosilicon, wastewater treatment, and mineral processing. This article will provide a brief introduction to the manufacturing methods of Sodium hydrosulfide, including raw materials, process flow, operational steps, equipment, quality control, and safety measures.

Raw materials

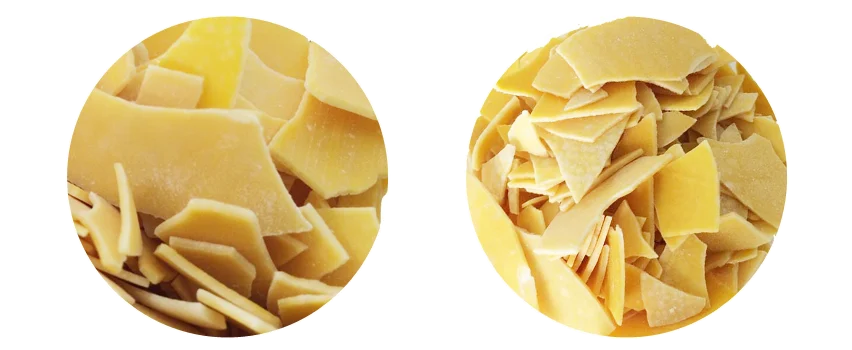

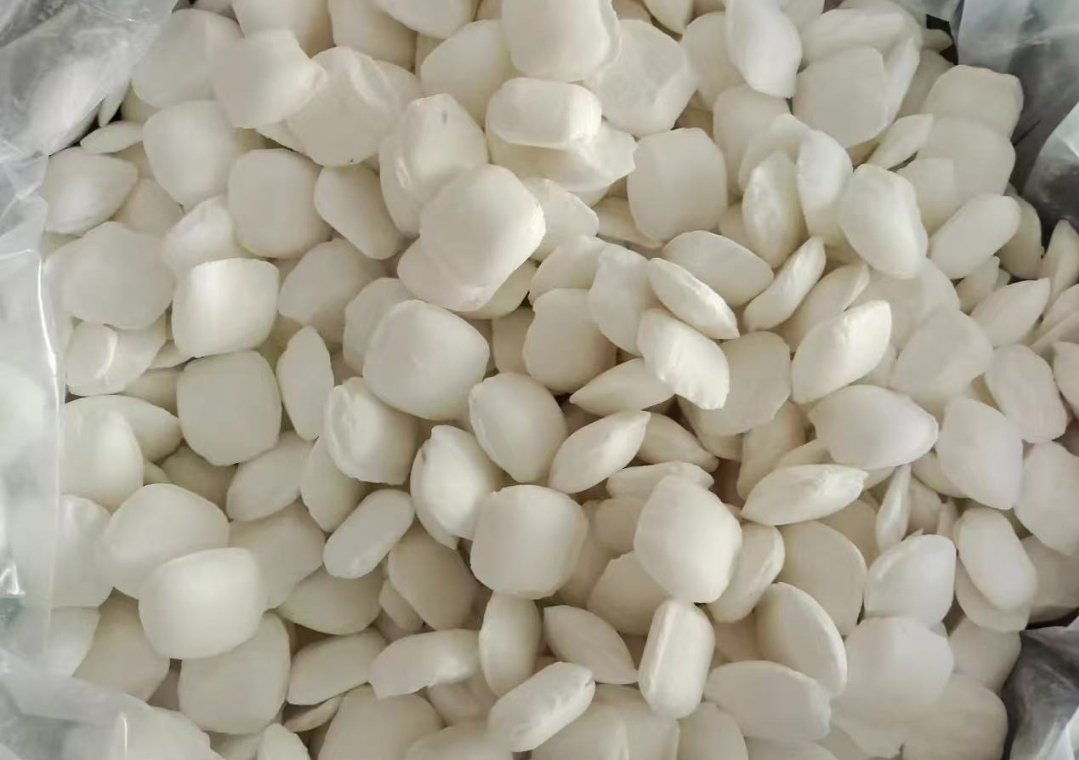

The main raw materials for the production of sodium hydrosulfide (NaHS) are sodium hydroxide and hydrogen sulfide. The sodium hydroxide should be of industrial grade with a purity of no less than 96%, and the hydrogen sulfide gas should comply with relevant national standards.

Process Flow

Preparation of Sodium Hydroxide Solution: Solid sodium hydroxide is added to an appropriate amount of water and stirred to dissolve, forming a sodium hydroxide solution.

Introduction of Hydrogen Sulfide: Hydrogen sulfide gas is introduced into the sodium hydroxide solution to react and produce sodium hydrosulfide.

Centrifugal Separation: The crystallized material is subjected to centrifugal separation to obtain the finished product of sodium hydrosulfide.

Drying: The sodium hydrosulfide product obtained from centrifugal separation is then dried.

Operational Steps

According to the specified ratio, add solid sodium hydroxide to the dissolution tank, then add an appropriate amount of water and stir to dissolve, forming a sodium hydroxide solution.

Open the hydrogen sulfide gas valve and introduce hydrogen sulfide gas into the sodium hydroxide solution, controlling the gas flow rate and reaction temperature to facilitate the reaction that produces sodium hydrosulfide.

When the pH of the reaction mixture reaches a certain value, stop the gas flow, cool the reaction mixture to a specific temperature, and allow sodium hydrosulfide to crystallize out.

Place the crystallized material into a centrifuge for centrifugal separation to obtain the finished product of sodium hydrosulfide.

Transfer the sodium hydrosulfide product obtained from centrifugal separation into a drying device for drying treatment to obtain the final sodium hydrosulfide product.

Equipment

The equipment required for the production of sodium hydrosulfide includes a dissolution tank, reaction kettle, crystallization tank, centrifuge, and drying equipment. These devices should comply with relevant production standards and safety requirements, and they need to undergo regular maintenance and inspection to ensure normal operation and safe usage.

Quality Control

Hydrogen sulfide gas is toxic and harmful, so it is essential to strictly control the gas flow rate and reaction temperature to prevent gas leaks and incidents of personnel poisoning.

The production site should be equipped with safety warning signs and fire-fighting facilities to ensure personnel safety and enhance emergency response capabilities.

Operators must undergo professional training to understand the properties of the product and the operating procedures, ensuring the safety and stability of the operation process.

As an important chemical raw material, sodium hydrosulfide requires strict control over factors such as raw material quality, reaction conditions, and product quality during the manufacturing process to ensure the quality and yield of the product. Additionally, it is essential to strengthen the implementation and management of safety measures to ensure the safety and stability of the production process.

- Random Content

- Hot content

- Hot review content

- Sodium bisulfite 99% High Quality Factory Supply

- Toluene

- Barium carbonate 99% powder

- Dodecylbenzenesulfonic acid

- Diethylene Glycol

- 99.9% Purity Ethyl Acetate

- Polytetramethylene / PTMG / Polybutylene glycol

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Sodium Hydroxide,Caustic Soda Flakes,Caustic Soda Pearls 96%-99%

- 5Nutritional Supplements Food Addictive Sarcosine 99% min

- 6Sodium Cyanide Import Regulations & Compliance – Ensuring Safe and Compliant Importation in Peru

- 7United Chemical's Research Team Demonstrates Authority Through Data-Driven Insights

Online message consultation

Add comment: