Firstly, cyanide sodium gold extraction, also known as cyanide leaching, is a long-established process. Currently, nearly 30% of the world's gold is extracted using this method, indicating its widespread application.

Advantages: Low cost and effective leaching.

Disadvantages: Environmental issues.

In fact, the traditional cyanide pool leaching process has long been listed for elimination. Nowadays, most methods involve cyanide heap leaching or in-situ leaching, but these are also gradually being phased out, as there is currently no better technology to replace them.

Sodium cyanide is highly toxic, so strict management and control are required before and after its use.

Let me summarize the process of mineral processing (or beneficiation). This topic may seem distant to the general public, as many people are unaware that after ore is mined, it must go through the mineral processing stage. In the eyes of the average person, iron ore is simply mined and then directly smelted into iron, right? However, this idea is completely incorrect. Most ores are typically low-grade and contain a lot of impurities, making them unsuitable for direct smelting. Additionally, the presence of too many impurities complicates the smelting process, increases costs, and results in poor quality products. Therefore, there is a necessary step of mineral processing between mining and smelting.

For example, if you mine an iron ore with an iron content (grade) of 40%, directly smelting it could lead to harmful impurities like phosphorus, making the resulting steel brittle. What can be done? The ore can be processed to increase the iron content to 60% through methods such as gravity separation, magnetic separation, and grinding, resulting in a 60% grade iron concentrate. This iron concentrate has had a significant amount of impurities removed and can be directly used for smelting.

Similarly, ores like lead, zinc, copper, molybdenum, and nickel also require such mineral processing to concentrate valuable minerals and remove impurities, providing qualified raw materials for smelting.

From the above explanation, one should understand the necessity of mineral processing. What about gold ore?

Of course, gold ore also requires mineral processing.

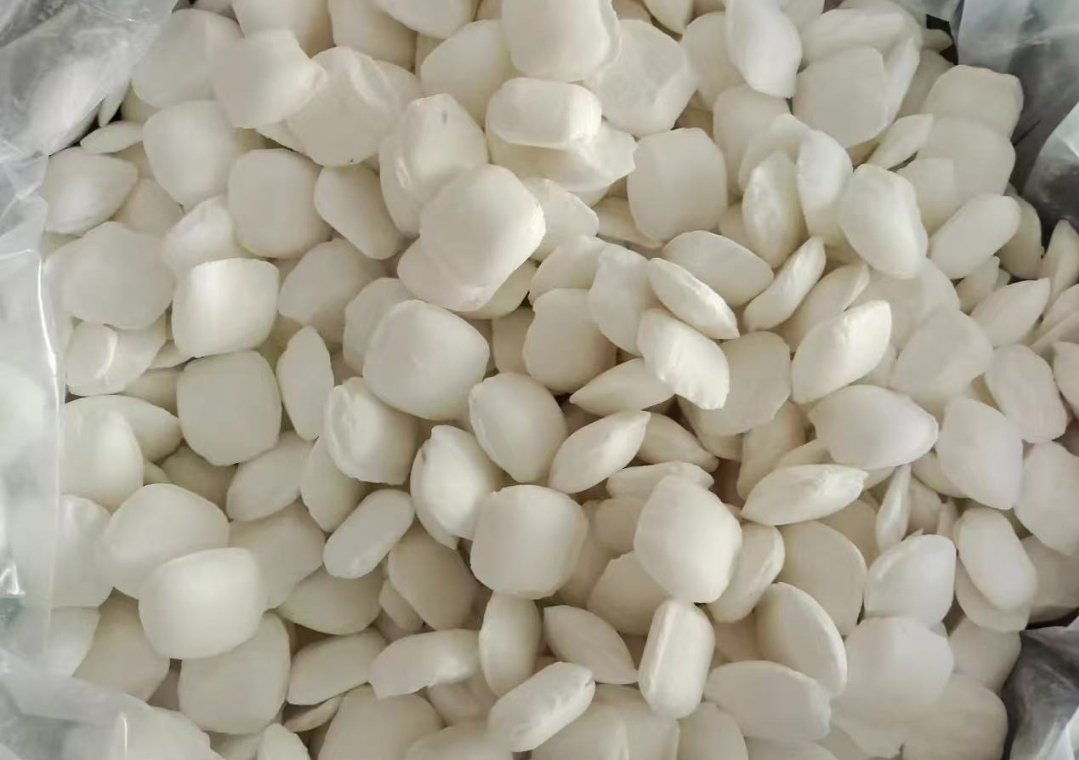

Ordinary lead-zinc ores typically have a combined grade of around 5% or more, with some lower-grade ores around 2%. However, gold ore is different. The grade of gold ore is measured in grams per ton (g/t). Many gold ores have grades of only 1 g/t or 2 g/t, meaning that from one ton of gold ore, there may only be 1 gram or 2 grams of gold. How is this gold extracted? It is typically done using cyanide, which dissolves the gold from the ore, and then activated carbon is used to adsorb and elute the gold, resulting in a gold sludge that can be refined into gold bars. The cyanide process is currently the most cost-effective and economical method.

Is there any other substance that can dissolve gold and replace cyanide?

In fact, there are many substances that can dissolve gold, but finding a realistic alternative to Sodium cyanide is quite challenging.

Thiourea can dissolve gold, but the required dosage is very large, making it too expensive!

Polysulfides and lime sulfur can also be used, but they require copper ammonia ions, and the dosage is similarly high, leading to high costs.

There are also biological leaching methods, but these are still in the experimental stage.

The most widely used alternatives are new leaching agents like JINCHAN and JINFU. Whether these agents contain cyanide is debatable, and their effectiveness is also a matter of discussion. Some mines have already applied them with decent results, but large-scale promotion or the hope that they can be as universally applicable as Sodium Cyanide for most gold mines is still quite difficult.

Therefore, the cyanide process remains the mainstream method.

The cyanide-free leaching agents or processes invented by researchers in mineral processing face significant challenges in promotion and support from relevant departments, making it hard to implement widely. After all, those in the industry know that sodium cyanide is effective, easy to use, and cost-efficient—who wouldn't want to maximize profits?

To replace the cyanide process, it is difficult without strong national support for promotion or funding for related research.、

Is it true that cyanidation processes, being mainstream, must necessarily harm the environment?

Countries have various environmental protection policies, and there are strict treatment methods and regulations for mining wastewater, leaching solutions, and waste residues.

In fact, how dangerous can sodium cyanide really be? It is true that ingesting it can be fatal. However, it can be treated; by adding bleaching powder, it can be decomposed through redox reactions. Many countries have corresponding policies, regulations, and standards to regulate this matter.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

- Random Content

- Hot content

- Hot review content

- Plastic Shock Tube(VOD≧1600m/s)

- Sodium Metal, ≥99.7%

- High-strength, High-precision Shock Tube Detonator

- Digital Electronic Detonator(Delay time 0~ 16000ms)

- Thiourea 99% high activity Professional Producer

- Food Grade Heavy Light Precipitated Calcium Carbonate Powder Granular 99%

- United Chemical GDA Gold Dressing Agent HS: 3824999999 – Eco-Friendly Substitute for Sodium Cyanide

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 3Sodium Cyanide 98%+ CAS 143-33-9

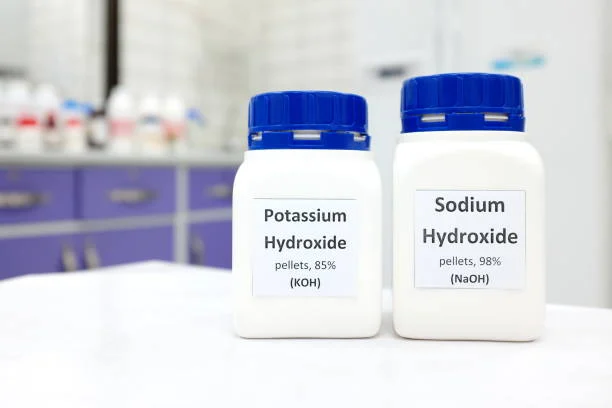

- 4Sodium Hydroxide,Caustic Soda Flakes,Caustic Soda Pearls 96%-99%

- 5Nutritional Supplements Food Addictive Sarcosine 99% min

- 6Sodium Cyanide Import Regulations & Compliance – Ensuring Safe and Compliant Importation in Peru

- 7United Chemical's Research Team Demonstrates Authority Through Data-Driven Insights

Online message consultation

Add comment: