How to convert sodium hydrosulfide liquid into solid?

What should be noted during the tablet-making process?

Industrial sodium hydrosulfide liquid is an inorganic compound with the chemical formula NaHS. It is usually a colorless or light yellow liquid with a strong pungent odor. It is an important industrial raw material and is widely used in many fields. Chemical properties and uses Industrial sodium hydrosulfide liquid is alkaline in chemical properties and is easily soluble in water and alcohol. Its main uses include: Dye industry: used as an auxiliary agent for the synthesis of Organic Intermediates and the preparation of Sulphur Dyes. Leather industry: used for dehairing and tanning of raw hides. Fertilizer industry: used to remove monomeric sulfur in activated carbon desulfurizers. Mining industry: used in large quantities for Copper Ore Dressing. Man-made fiber production: used for dyeing, etc. Wastewater treatment: used for Wastewater Treatment, etc.

1. Steps to Convert Sodium Hydrosulfide Liquid into Flakes

Concentration of Sodium Hydrosulfide Solution: First, concentrate the sodium hydrosulfide aqueous solution to a concentration of 68-72%, while maintaining a temperature of no less than 70°C.

Heat Preservation Treatment: After concentration, the sodium hydrosulfide solution undergoes heat preservation treatment to maintain an appropriate temperature for the subsequent flaking process.

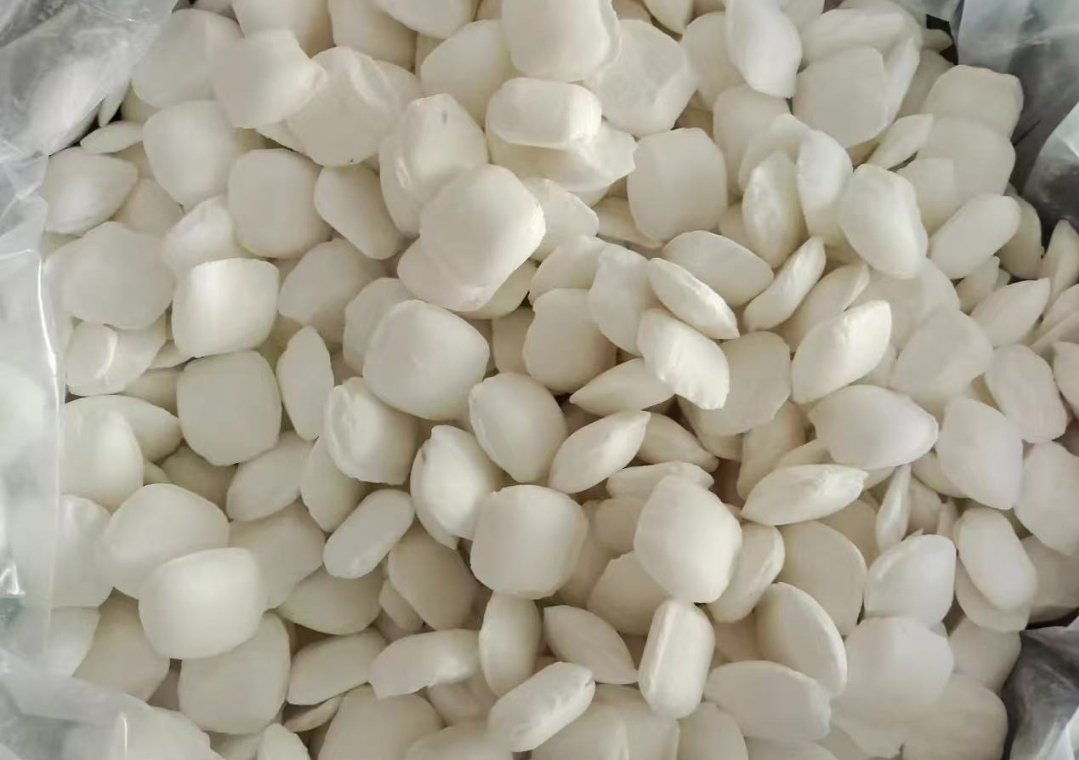

Cooling and Flaking: The heat-preserved sodium hydrosulfide solution is sent to the surface of a rotating drum in a cold flaking machine. Cold water is introduced through the cooling holes of the drum, allowing the sodium hydrosulfide solution to cool and solidify on the drum's surface.

Scraping and Packaging: A scraper is used to remove the sodium hydrosulfide from the surface of the drum, forming irregular flakes. The thickness of the scraped flakes is approximately 0.5-2.0 mm. The flakes are then sealed in packaging bags using standard methods.

Environmental Control: To ensure the normal operation of the flaking machine and the proper solidification of the sodium hydrosulfide solution on the drum surface, it is necessary to control the working environment of the flaking machine, keeping the temperature below 18°C and the relative humidity below 80%.

2. What should be noted during the flaking process of sodium hydrosulfide liquid?

Safety Protection: Due to the irritating odor of sodium hydrosulfide and its tendency to volatilize, appropriate protective clothing, gloves, and goggles or masks should be worn during operation. Inhalation of sodium hydrosulfide gas should be avoided, as it is highly toxic and may lead to poisoning.

Operating Environment: Sodium hydrosulfide should be handled in a well-ventilated environment to reduce the risk of inhaling toxic gases.

Avoid Contact with Oxidizers and Acids: During use, sodium hydrosulfide should be kept away from oxygen, oxidizers, and other substances to prevent fire or explosion. Additionally, sodium hydrosulfide should not be mixed with acids, as this can release toxic gases.

Skin and Eye Contact: Sodium hydrosulfide solution can irritate the skin and eyes, so protective gloves and goggles should be worn during use.

Storage and Transportation: Sodium hydrosulfide should be stored in a sealed container in a well-ventilated, dry storage area. During transportation, it should be protected from rain and sunlight. Sodium hydrosulfide in iron drums should be transported in covered vehicles, while liquid sodium hydrosulfide should be transported in tankers. Packaging should remain intact, and it should not be laid down or inverted, nor should it come into contact with acids.

Fire and Corrosion Prevention: During transportation, precautions should be taken to prevent fire and corrosion. It should be stored and transported away from food and items that may react with hydrogen sulfide.

Emergency Handling: In the event of leakage from packaging, the area should be cleaned with water, and the container should be sealed tightly. In case of fire, water, sand, or various fire extinguishers can be used to extinguish the flames.

Cooling Water Temperature: The temperature of the cooling water should be controlled to not exceed 15°C.

The above are the steps and main issues that need to be paid attention to when making sodium hydrosulfide liquid into flakes. Following these precautions can ensure the safety and efficiency of the production process.

- Random Content

- Hot content

- Hot review content

- Thiourea 99% high activity Professional Producer

- Phthalic anhydride

- lithium Carbonates 99.5% Battery Level or 99.2% Industry grade 99%

- Sodium alpha olefin sulfonate (AOS)

- Sodium selenite,anhydrous 98%

- Fuel Additive Octane Value Booster Ferrocene

- What is a settling agent, and how does it work in mining?

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Sodium Hydroxide,Caustic Soda Flakes,Caustic Soda Pearls 96%-99%

- 5Nutritional Supplements Food Addictive Sarcosine 99% min

- 6Sodium Cyanide Import Regulations & Compliance – Ensuring Safe and Compliant Importation in Peru

- 7United Chemical's Research Team Demonstrates Authority Through Data-Driven Insights

Online message consultation

Add comment: