Sodium cyanide (NaCN), as a core reagent for gold extraction, has dominated the global gold mining industry due to its characteristic of efficiently dissolving gold. However, with the increasing environmental protection requirements and technological advancements, the traditional cyanidation method is facing multiple challenges in terms of cost, safety, and sustainability. This article will deeply analyze the application mechanism of Sodium Cyanide in Gold Ore Extraction and explore the technological innovations that have been driving the industry's transformation in recent years.

I. The Core Principles and Current Application Status of the Cyanidation Method

1. Chemical Dissolution Mechanism

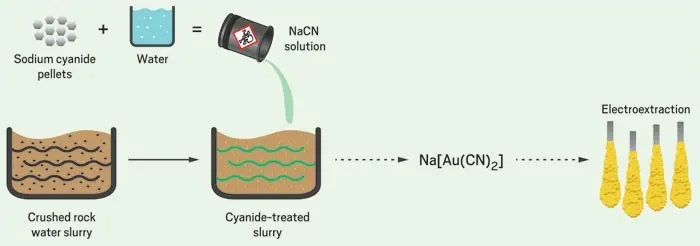

Sodium cyanide dissolves gold through the following reaction:

4Au + 8NaCN + O₂ + 2H₂O → 4NaAu(CN)₂ + 4NaOH

This reaction occurs in an alkaline environment (pH 10-11), and continuous oxygen supply is required to maintain the oxidation state of gold. Although the gold recovery rate of the cyanidation method is as high as over 90%, its toxicity and environmental risks have prompted the industry to seek improvements.

2. Directions for Technological Optimization

Low-concentration Cyanide Process: Reducing the cyanide concentration from 0.1% to 0.01%-0.03%, which can decrease the consumption of reagents and the risk of leakage;

Enhancing Leaching Efficiency: Pretreating ores through ultrasonic or microwave technology, or adding catalysts (such as lead salts) to accelerate the reaction;

Closed-loop Circulation System: Achieving a recycling rate of over 95% for the cyanide solution and reducing emissions.

II. Technological Challenges Faced by the Cyanidation Method

1. Complexity of Ores

Refractory Ores: Sulfide ores containing arsenic and sulfur require pre-oxidation (such as roasting or pressure oxidation), increasing the cost;

Interference of Impurities: Metal ions such as copper and iron consume cyanide, leading to a 30%-50% increase in the dosage of reagents.

2. Environmental and Safety Pressures

Risk of Cyanide Leakage: On average, there are about 20 cyanide leakage accidents globally each year, threatening water sources and the ecosystem;

High-energy Consumption in Pretreatment: The energy consumption of traditional oxidation processes accounts for more than 40% of the total cost.

III. Technological Innovations: From Traditional to Green Processes

1. Breakthroughs in Cyanide-free Leaching Technologies

Thiourea Leaching Method: Using an acidic thiourea solution (pH 1.5-2.5) to dissolve gold, with the reaction formula:

Au + 2CS(NH₂)₂ + Fe³⁺ → Au[CS(NH₂)₂]₂⁺ + Fe²⁺

Advantages: Non-toxic, suitable for low-grade oxidized ores;

Limitations: The acidic conditions are likely to corrode equipment, and the cost is 15%-20% higher than that of the cyanidation method.

Bromination Leaching Method: Adopting a sodium bromide/potassium bromate system, with a gold recovery rate of up to 92%, and the leaching rate is 3 times faster than that of the cyanidation method.

2. Biological Leaching and Nanotechnology

Microbial Pretreatment: Using Thiobacillus ferrooxidans to decompose sulfide ores, releasing gold from the mineral encapsulation and reducing the energy consumption of pre-oxidation by 30%;

Adsorption by Nanomaterials: Graphene oxide can selectively adsorb Au(CN)₂⁻, with an adsorption capacity of up to 500 mg/g, which is 3 times higher than that of activated carbon.

3. Digital and Intelligent Upgrades

Prediction of Slurry Concentration by AI: Optimizing the slurry concentration through a machine learning model, reducing the waste of cyanide by 10%-15%;

Traceability via Blockchain: Recording the whole life cycle data of cyanide to enhance the transparency of supervision.

IV. Typical Cases and Industry Practices

1. Newmont Corporation in Canada

Innovation: Adopting the technology of "Biological Leaching + membrane separation" to treat refractory ores;

Achievements: Reducing the consumption of cyanide by 60% and increasing the gold recovery rate to 94%.

2. Zijin Mining Group in China

Technology: Independently developing the "low-cyanide and high-efficiency gold leaching agent", reducing the dosage of cyanide by 40%;

Application: Promoting it in a certain gold mine in Guizhou, saving over 20 million yuan in costs annually.

V. Future Trends and Prospects

Dominance of Green Processes: It is expected that by 2030. cyanide-free leaching technologies will account for 30% of the market share;

Intelligent Mines: AI and the Internet of Things (IoT) will enable real-time monitoring of the whole process, reducing the accident rate by 80%;

Circular Economy Model: Increasing the recovery rate of cyanide from the current 60% to 90%, and utilizing by-products (such as ammonium sulfate) for resource recycling.

Conclusion

The application of sodium cyanide in gold ore extraction is undergoing a transformation from a "high-pollution" to a "high-technology" approach. Although the cyanidation method will still dominate in the short term, the breakthroughs in cyanide-free leaching, biological engineering, and digital technologies indicate that gold mining will enter a new era that is safer, more efficient, and more sustainable. In the future, the synergistic effect of technological innovation and policy guidance will reshape the industry landscape, achieving a win-win situation between economic benefits and ecological protection.

- Random Content

- Hot content

- Hot review content

- Salicylhydroxamic acid / Salicyl Hydroximic Acid 60%Min

- Fertilizer magnesium sulfate/magnesium sulfate monohydrate

- Phthalic anhydride

- Adipic acid 99% used as the material of nylon 66

- Sodium alpha olefin sulfonate (AOS)

- Sodium Dimethyldithiocarbamate 95% solid, 40% liquid

- Strontium carbonate

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Sodium Hydroxide,Caustic Soda Flakes,Caustic Soda Pearls 96%-99%

- 5Nutritional Supplements Food Addictive Sarcosine 99% min

- 6Sodium Cyanide Import Regulations & Compliance – Ensuring Safe and Compliant Importation in Peru

- 7United Chemical's Research Team Demonstrates Authority Through Data-Driven Insights

Online message consultation

Add comment: