2026 Industry Research Report on Coconut Shell Activated Carbon for Gold Recovery

1. Industry Overview in 2026

By 2026, coconut shell activated carbon remains the most widely adopted adsorption material in global gold recovery processes, particularly in CIP, CIL, CIC, and heap leaching systems. Despite the emergence of alternative carbon sources and synthetic adsorbents, fruit shell–based activated carbons continue to dominate gold mining applications due to their structural stability, adsorption efficiency, and proven industrial performance.

Among fruit shell carbons, coconut shell activated carbon is regarded as the industry benchmark, while apricot shell, peach shell, and other fruit shell carbons are used in limited or specialized scenarios depending on ore characteristics and operating conditions.

2. Role of Activated Carbon in Gold Recovery Processes

In cyanide leaching systems, activated carbon is used to adsorb dissolved gold in the form of the dicyanoaurate complex Au(CN)₂⁻ from leach solutions or pulp.

The performance of activated carbon directly affects:

Gold adsorption rate

Residual gold concentration in tailings

Carbon loading capacity

Elution efficiency and carbon regeneration cycles

High-quality activated carbon enables faster adsorption kinetics, lower gold losses, and longer service life, making it a critical consumable rather than a simple auxiliary material.

3. Main Types of Fruit Shell Activated Carbon Used in Gold Mining

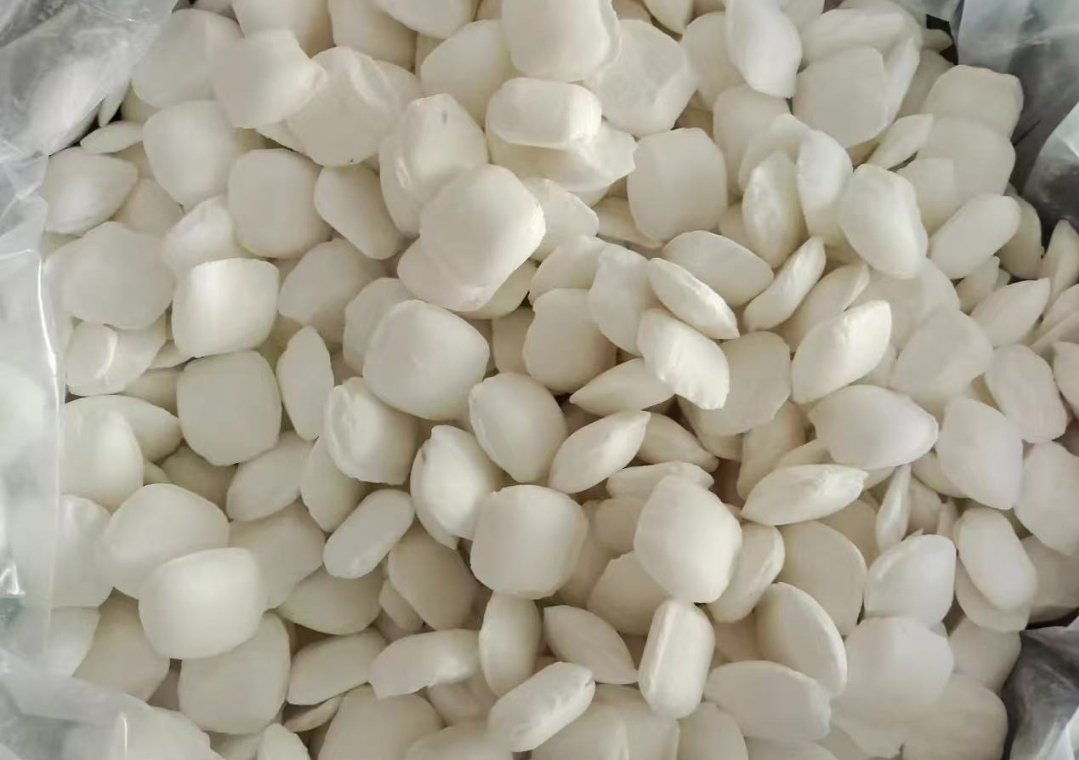

3.1 Coconut Shell Activated Carbon

Produced from coconut shells through high-temperature carbonization and activation, coconut shell carbon features:

Highly developed microporous structure

High mechanical strength

Excellent resistance to abrasion

Stable adsorption behavior over multiple cycles

It is the preferred choice for large-scale, continuous gold recovery operations.

3.2 Apricot Shell Activated Carbon

Apricot shell carbon generally exhibits:

Moderate pore development

Lower hardness compared to coconut shell carbon

Acceptable adsorption performance in low-abrasion systems

It is sometimes used in small-scale or cost-sensitive operations, but requires careful control of operating conditions.

3.3 Peach Shell Activated Carbon

Peach shell carbon is characterized by:

Relatively uneven pore size distribution

Lower mechanical strength

Higher tendency to generate carbon fines

Its application in gold recovery is limited and typically restricted to low pulp density systems.

3.4 Other Fruit Shell Activated Carbons

This category includes activated carbons derived from:

Walnut shells

Palm shells

Mixed agricultural by-products

Their performance varies significantly depending on raw material quality and activation process, making them less standardized for gold mining applications.

4. Product Standards Comparison for Gold Recovery Activated Carbon

4.1 Key Performance Indicators (Typical Industry Ranges)

| Parameter | Coconut Shell Carbon | Apricot Shell Carbon | Peach Shell Carbon | Other Fruit Shell Carbon |

|---|---|---|---|---|

| Iodine number (mg/g) | ≥1000 | 900–1000 | 850–950 | 800–950 |

| Gold loading capacity | ≥25 kg Au/t C | 18–25 | 15–20 | 12–20 |

| Hardness (%) | ≥99 | 95–97 | 92–95 | 90–95 |

| Ash content (%) | ≤3 | 3–5 | 4–6 | 4–7 |

| Carbon fines generation | Very low | Low–medium | Medium | Medium–high |

| Service life | Long | Medium | Short | Variable |

👉 In 2026, high-efficiency gold recovery operations prioritize overall performance balance rather than a single parameter such as iodine number.

5. Interpretation of Gold Recovery Efficiency

5.1 Adsorption Performance

Coconut shell activated carbon consistently demonstrates:

Faster gold adsorption kinetics

Higher equilibrium loading

Better selectivity for gold complexes

Alternative fruit shell carbons may perform adequately under controlled conditions but often show greater sensitivity to pulp chemistry and mechanical stress.

5.2 Impact on Overall Plant Performance

The choice of activated carbon affects:

Carbon inventory turnover

Frequency of carbon replacement

Gold losses in tailings

Stability of elution and electrowinning circuits

In low-grade gold ores, even a small reduction in adsorption efficiency can significantly impact project economics.

6. Coconut Shell Carbon vs Other Fruit Shell Activated Carbons (Summary)

| Aspect | Coconut Shell | Apricot Shell | Peach Shell | Other Fruit Shells |

|---|---|---|---|---|

| Gold adsorption efficiency | Excellent | Good | Moderate | Variable |

| Mechanical strength | Excellent | Good | Fair | Fair |

| Abrasion resistance | Excellent | Good | Moderate | Moderate |

| Consistency | Very high | Medium | Low | Low |

| Suitability for CIP/CIL | Ideal | Conditional | Limited | Limited |

7. Industry Trends and Procurement Considerations in 2026

Industry Trends

Growing emphasis on long-term operating cost rather than unit price

Increased demand for customized activated carbon matched to ore characteristics

Mandatory laboratory adsorption tests before bulk procurement

Procurement Recommendations

Evaluate both hardness and gold loading capacity

Conduct site-specific adsorption and abrasion tests

Avoid selecting products based solely on iodine number

8. Conclusion

In 2026, coconut shell activated carbon remains the preferred and most reliable adsorption material for gold recovery. While apricot shell, peach shell, and other fruit shell activated carbons may find application in niche scenarios, their limitations in mechanical strength and long-term stability restrict widespread adoption in modern gold processing plants.

For mining operations aiming at high recovery, stable operation, and predictable costs, coconut shell activated carbon continues to represent the industry standard.

- Random Content

- Hot content

- Hot review content

- High-strength Shock tube(VOD≧2000m/s)

- Sodium bisulfite 99% High Quality Factory Supply

- Seismic Electric Detonator(Anti static,Water Resistance)

- 99.5% min Ammonium Chloride For Industrial Use

- Thiourea 99% high activity Professional Producer

- Barium carbonate 99% powder

- Pharmaceutical Grade Zinc Acetate

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Sodium Hydroxide,Caustic Soda Flakes,Caustic Soda Pearls 96%-99%

- 5Nutritional Supplements Food Addictive Sarcosine 99% min

- 6Sodium Cyanide Import Regulations & Compliance – Ensuring Safe and Compliant Importation in Peru

- 7United Chemical's Research Team Demonstrates Authority Through Data-Driven Insights

Online message consultation

Add comment: