Sodium cyanide is a highly toxic chemical compound that poses significant health risks if mishandled. Known for its lethal potential, even trace amounts of Sodium cyanide can lead to poisoning and death through skin contact, inhalation, or ingestion. Despite its dangers, Sodium Cyanide is a crucial raw material in various industries, including machinery, chemicals, pharmaceuticals, and metallurgy. Therefore, understanding the safety protocols for transporting this hazardous substance is essential to prevent accidents and ensure the safety of workers and the environment.

Understanding Sodium Cyanide

Sodium cyanide is primarily used in the extraction of gold and silver from ores, as well as in the production of certain chemicals and pharmaceuticals. Its effectiveness in these applications makes it a valuable commodity, but its toxicity necessitates stringent safety measures during transportation and storage.

Key Issues to Consider When Transporting Sodium Cyanide

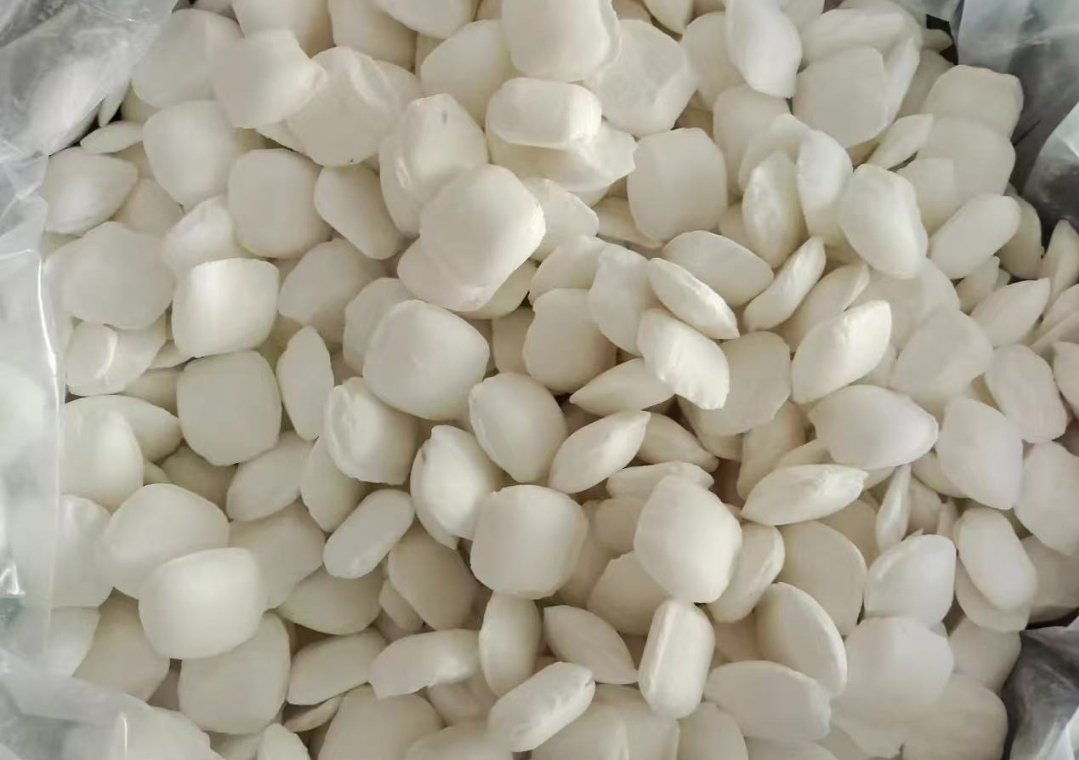

1. Proper Packaging:

Sodium cyanide should be securely packed to prevent leaks and spills during transportation. Solid or liquid forms of sodium cyanide must be contained in robust wooden boxes, iron tubes, or iron barrels. This packaging not only protects the chemical from external elements but also minimizes the risk of accidental exposure.

2. Storage Conditions:

The storage of sodium cyanide requires a dry and well-ventilated environment. Ideally, it should be kept in a dedicated warehouse designed specifically for hazardous materials. Access to this warehouse should be restricted and monitored, with two personnel required to manage entry and exit. The use of double locks is recommended to enhance security and prevent unauthorized access.

3. Personal Protective Equipment (PPE):

Workers who handle sodium cyanide must be equipped with appropriate personal protective equipment. This includes work clothes, gas masks, gloves, and other protective gear. It is crucial that workers adhere to these safety protocols to minimize the risk of exposure. After completing their tasks, workers should remove all protective equipment and wash their hands, faces, and any exposed skin thoroughly with water. Additionally, disinfecting with a dilute sodium hypochlorite solution is advised before rinsing with water to ensure any residual cyanide is neutralized.

4. Hygiene Practices:

Maintaining hygiene is vital when working with sodium cyanide. Workers should refrain from consuming food, beverages, or tobacco products during breaks to avoid accidental ingestion of the chemical. It is also important to avoid contact with any open wounds or skin abrasions, as this can lead to serious health consequences.

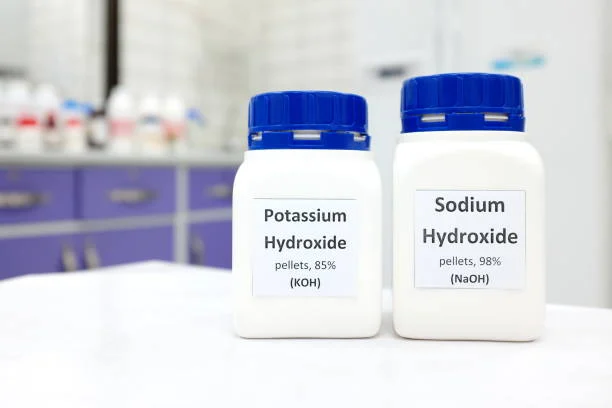

5. Avoiding Chemical Reactions:

Sodium cyanide should never be stored or transported alongside acids, chlorates, sodium nitrite, or edible raw materials. These substances can react dangerously with sodium cyanide, potentially leading to hazardous situations. Additionally, it is crucial to keep the containers tightly sealed to prevent moisture exposure, which can compromise the integrity of the chemical.

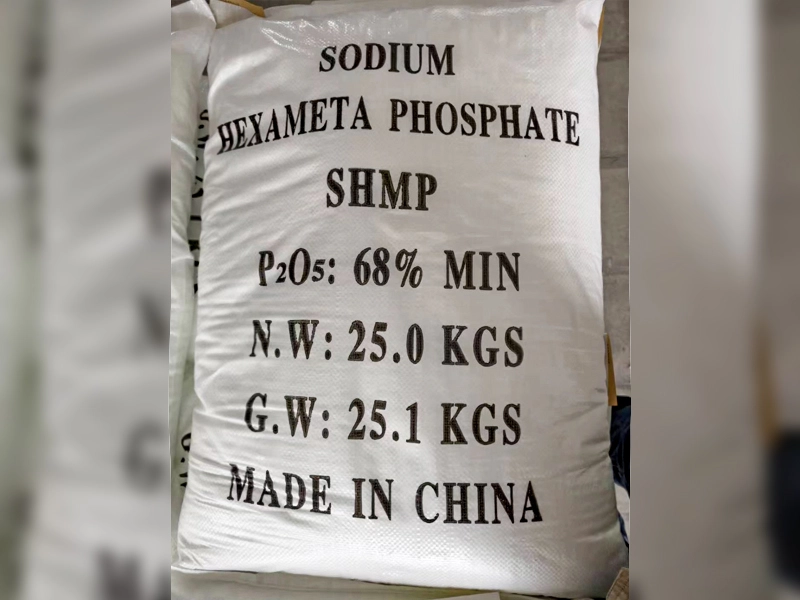

6. Handling Spills and Leaks:

In the event of a leak or spill, immediate action is required to mitigate risks. Workers should wear gas masks and gloves when handling the leaked material. The recommended procedure involves adding an excess of sodium hypochlorite solution to the spill area and allowing it to sit for 24 hours. This process ensures that the sodium cyanide is completely decomposed. After the designated time, the diluted solution can be disposed of through the wastewater system, following local regulations.

7. Decontamination Procedures:

After addressing a spill, the contaminated area must be treated with a sodium hypochlorite solution for 24 hours. Following this, the area should be rinsed thoroughly with a large volume of water. The rinse water, which may contain residual cyanide, should also be disposed of in accordance with wastewater management protocols to prevent environmental contamination.

Conclusion

Transporting sodium cyanide requires meticulous attention to safety protocols to protect workers, the public, and the environment. By adhering to proper packaging, storage, and handling procedures, the risks associated with this hazardous chemical can be significantly reduced. It is imperative that all personnel involved in the transportation and handling of sodium cyanide are adequately trained and equipped with the necessary protective gear. Regular safety drills and reviews of emergency procedures can further enhance preparedness and response capabilities in the event of an incident.

In summary, while sodium cyanide is an essential chemical in various industries, its transportation and handling must be approached with caution and respect for its potential dangers. By implementing comprehensive safety measures, we can ensure that the benefits of sodium cyanide are realized without compromising safety or health.

- Random Content

- Hot content

- Hot review content

- Sulphuric Acid 98% Industrial Grade

- IPETC 95%Metal sulfide mineral collector Z-200

- Ammonium Nitrate Porous Prills

- Thiourea 99% high activity Professional Producer

- Ethyl alcohol /Ethanol 99.5%

- Zinc sulfate monohydrate 98% Industrial & Feed Grade

- Cobalt Sulfate 98% Brown yellow or red crystal

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 3China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Soda Ash Dense / Light 99.2% Sodium Carbonate Washing Soda

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 3Sodium Cyanide 98%+ CAS 143-33-9

- 4Sodium Hydroxide,Caustic Soda Flakes,Caustic Soda Pearls 96%-99%

- 5Nutritional Supplements Food Addictive Sarcosine 99% min

- 6Sodium Cyanide Import Regulations & Compliance – Ensuring Safe and Compliant Importation in Peru

- 7United Chemical's Research Team Demonstrates Authority Through Data-Driven Insights

Online message consultation

Add comment: