Introduction

Mineral flotation is a widely used method in the mining industry to separate valuable minerals from gangue minerals. It relies on the differences in the physical and chemical properties of mineral surfaces. Sodium hexametaphosphate, with its unique chemical structure and properties, has found significant applications in Mineral flotation processes. This article delves into the various aspects of its use in mineral flotation.

Properties of Sodium Hexametaphosphate

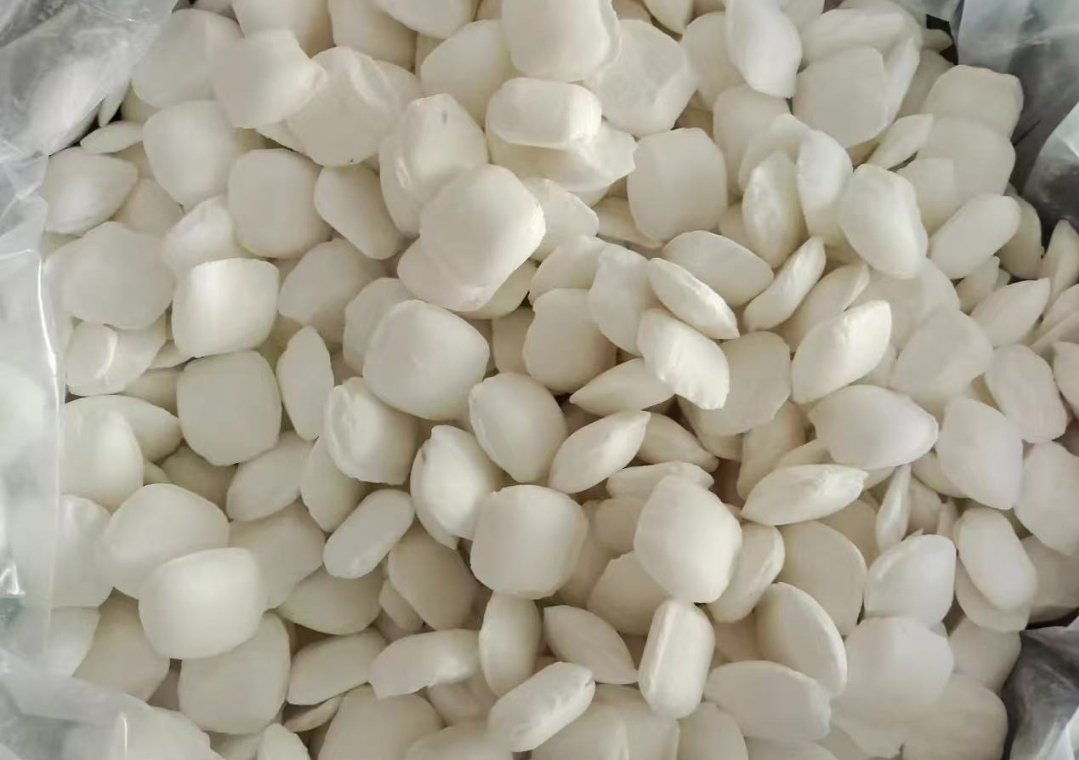

Sodium hexametaphosphate is an inorganic polymer compound. It appears as a colorless transparent crystal or white powder. It is highly soluble in water, and its aqueous solution is alkaline. In the air, it has a certain degree of hygroscopicity. These physical and chemical properties lay the foundation for its functionality in mineral flotation.

Roles in Mineral Flotation

Depressant

1.Inhibition of Silicate and Carbonate Minerals

Sodium hexametaphosphate is effective in inhibiting quartz and silicate minerals. In the flotation of some ores, such as those containing feldspar and mica, it can adsorb on the surface of these silicate minerals. For example, in the flotation of zirconium ores, it can reduce the floatability of associated feldspar and other silicate gangue minerals by adsorbing on their surfaces.

It also shows inhibitory effects on carbonate minerals like calcite and limestone. In the flotation of phosphate ores where calcite is a common gangue mineral, Sodium hexametaphosphate can react with calcium ions on the calcite surface. It forms stable compounds that increase the hydrophilicity of the calcite surface, making it less likely to be attached by the collector, thus achieving the purpose of inhibition.

2.Inhibition Mechanism

One of the main inhibition mechanisms is related to its reaction with metal ions on the mineral surface. When it comes to minerals containing multi - valent metal ions, sodium hexametaphosphate can form stable compounds with these metal ions. In nickel ore flotation, it reacts with specific ions on the surface of serpentine, which inhibits the flotability of serpentine.

In addition, in the aqueous solution, sodium hexametaphosphate can ionize. It can react with calcium ions in the mineral surface and the liquid phase. In the separation of calcite and cassiterite, the compound formed on the calcite surface not only affects the calcite but also may adsorb on the cassiterite surface, reducing the selectivity of inhibition and decreasing the adsorption of the collector on the mineral surface.

Dispersant

1.Dispersion of Mineral Pulp

In flotation processes, especially for some ores with fine - grained minerals or high - mud - content ores, the dispersion of the mineral pulp is crucial. Sodium hexametaphosphate can play an important role as a dispersant. For example, in the flotation of nickel - pyrite ores associated with serpentine, adding an appropriate amount of sodium hexametaphosphate can disperse the flotation pulp. This is because it reduces the coverage of serpentine on the surface of nickel - pyrite, which is beneficial to the flotation recovery of nickel - pyrite.

2.Dispersion Mechanism

Sodium hexametaphosphate can lower the surface potential of minerals. As a result, the electrostatic repulsive force between mineral particles increases. Its molecular structure, a linear polymer compound with a chain length of at least 20 - 100 units, when adsorbed on the mineral surface, can also increase the steric hindrance effect between particles. In the flotation of some fine - grained phosphate ores, this dispersion effect can prevent the aggregation of phosphate and gangue minerals, improving the separation efficiency.

Application in Different Mineral Flotation

Phosphate Ore Flotation

1.Selective Separation

In phosphate ore flotation, sodium hexametaphosphate is often used to separate phosphate minerals from gangue minerals. Phosphate ores are often associated with various gangue minerals such as calcite, dolomite, and silicate minerals. Sodium hexametaphosphate can selectively inhibit these gangue minerals. In the reverse flotation process of some phosphate ores, adding a small amount of sodium hexametaphosphate can effectively increase the grade and recovery of phosphate concentrate. It can react with non - phosphate minerals without reacting with phosphate minerals, thus improving the selectivity of phosphate mineral flotation.

2.Effect on Foam Stability

It also has an impact on the foam stability in phosphate ore flotation. The foam in the flotation process plays a role in collecting phosphate minerals. Sodium hexametaphosphate can enhance the stability of the foam. It can generate a large number of stable foams, which helps to improve the collection effect of phosphate minerals. The phosphate minerals can be better carried by the stable foam to the surface, thereby improving the flotation efficiency and grade.

Non - Ferrous Metal Ore Flotation

1.Nickel Ore Flotation

As mentioned earlier, in nickel ore flotation, sodium hexametaphosphate is mainly used to inhibit serpentine. Serpentine is a common gangue mineral in nickel ores, and its presence can affect the flotation of nickel - bearing minerals. By adding sodium hexametaphosphate, it can react with the metal ions on the serpentine surface, reducing its floatability and improving the separation of nickel - bearing minerals from serpentine. This is beneficial for improving the grade and recovery of nickel concentrates.

2.Copper and Lead - Zinc Ore Flotation

In copper and lead - zinc ore flotation, when there are associated calcium - containing gangue minerals such as calcite and dolomite, sodium hexametaphosphate can be used to inhibit these gangue minerals. In some complex copper - lead - zinc ores, adjusting the amount of sodium hexametaphosphate can effectively control the floatability of gangue minerals, improving the selectivity of flotation and the quality of copper, lead, and zinc concentrates.

Factors Affecting the Application Effect

Dosage

1.Optimal Dosage Determination

The dosage of sodium hexametaphosphate has a significant impact on its performance in mineral flotation. An inappropriate dosage may lead to sub - optimal results. If the dosage is too low, it may not effectively inhibit gangue minerals or disperse the pulp. For example, in phosphate ore flotation, if the amount of sodium hexametaphosphate added is insufficient, the gangue minerals may not be well - inhibited, resulting in a lower grade of phosphate concentrate.

On the other hand, if the dosage is too high, it may not only increase costs but also cause some negative effects. In some cases, excessive sodium hexametaphosphate may also inhibit the target minerals to a certain extent, reducing the recovery rate. Therefore, determining the optimal dosage through experimental research and on - site debugging is crucial for achieving the best flotation results.

pH Value of the Pulp

2.Influence on Chemical Reactions

The pH value of the flotation pulp affects the chemical reactions of sodium hexametaphosphate. In different pH environments, the ionization degree and chemical form of sodium hexametaphosphate may change. In an acidic environment, its inhibitory effect on some minerals may be weakened. In a highly alkaline environment, it may react with other substances in the pulp, affecting its normal function. For example, in the flotation of some copper - lead - zinc ores, maintaining an appropriate pH value (usually around 8 - 10) can ensure that sodium hexametaphosphate effectively inhibits gangue minerals and promotes the flotation of target minerals.

Conclusion

Sodium hexametaphosphate plays multiple important roles in mineral flotation, including as a Depressant and a dispersant. Its applications in different types of mineral flotation, such as phosphate ore and non - ferrous metal ore flotation, have significantly improved the efficiency and quality of mineral separation. However, to fully exert its potential, factors such as dosage and pulp pH need to be carefully controlled. With the continuous development of the mining industry, further research on the application of sodium hexametaphosphate in mineral flotation may lead to more efficient and sustainable mineral processing methods.

- Random Content

- Hot content

- Hot review content

- Zinc Sulfate Industrial Grade 22%-35%

- Ferrous Sulfate Industrial Grade 90%

- Anhydrous Ammonia 99% Liquid

- Triethanolamine(TEA)

- Pharmaceutical Grade Zinc Acetate

- 2-Hydroxyethyl acrylate (HEA)

- Cupric Chloride 98%

- 1Discounted Sodium Cyanide (CAS: 143-33-9) for Mining - High Quality & Competitive Pricing

- 2China's New Regulations on Sodium Cyanide Exports and Guidance for International Buyers

- 3Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 4International Cyanide(Sodium cyanide) Management Code - Gold Mine Acceptance Standards

- 5China factory Sulfuric Acid 98%

- 6Anhydrous Oxalic acid 99.6% Industrial Grade

- 7Oxalic acid for mining 99.6%

- 1Sodium Cyanide 98% CAS 143-33-9 gold dressing agent Essential for Mining and Chemical Industries

- 2High Quality 99% Purity of Cyanuric chloride ISO 9001:2005 REACH Verified Producer

- 3Zinc chloride ZnCl2 for High Molecular Weight Polymers Initiator

- 4High Purity · Stable Performance · Higher Recovery — sodium cyanide for modern gold leaching

- 5High Quality Sodium Ferrocyanide / Sodium Hexacyanoferr

- 6Gold Ore Dressing Agent Safe Gold Extracting Agent Replace Sodium Cyanide

- 7Sodium Cyanide 98%+ CAS 143-33-9

Online message consultation

Add comment: